Signature Sign Guys

New Member

Hey Guys,

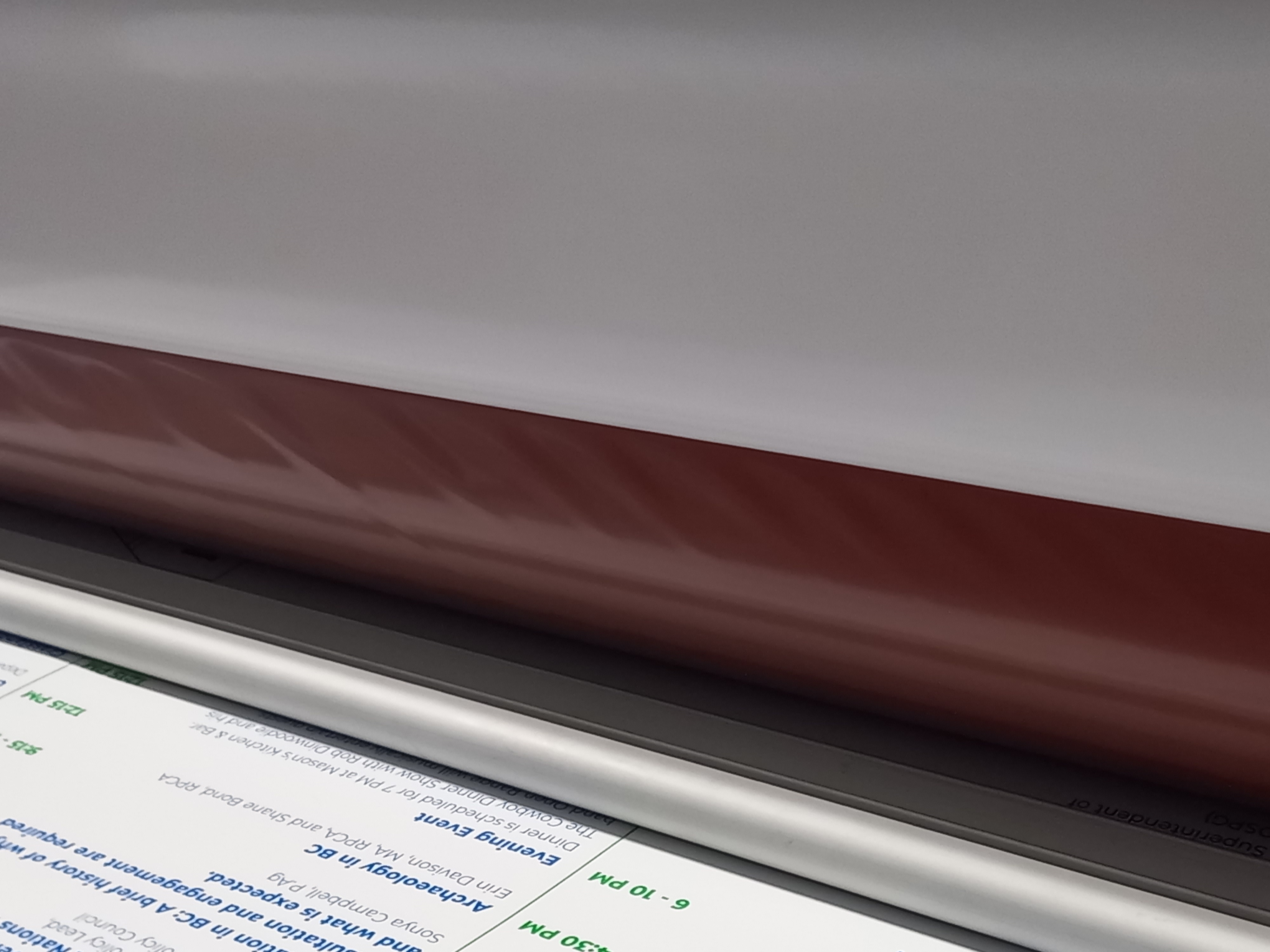

so i have always had issues when I laminate large prints (greater than 8ft) where everything starts on square and is laminating great and then my laminate starts to shift and skew. I can pull the laminate roll to the side and fix as its laminating but I shouldn't have to do that everytime I lam. Ive attached a photo of what I mean by skew. I just don't understand how starts square and even and then after 2-3 ft its starts to do this. Any ideas on how to trouble shoot this issue to fix it?

so i have always had issues when I laminate large prints (greater than 8ft) where everything starts on square and is laminating great and then my laminate starts to shift and skew. I can pull the laminate roll to the side and fix as its laminating but I shouldn't have to do that everytime I lam. Ive attached a photo of what I mean by skew. I just don't understand how starts square and even and then after 2-3 ft its starts to do this. Any ideas on how to trouble shoot this issue to fix it?