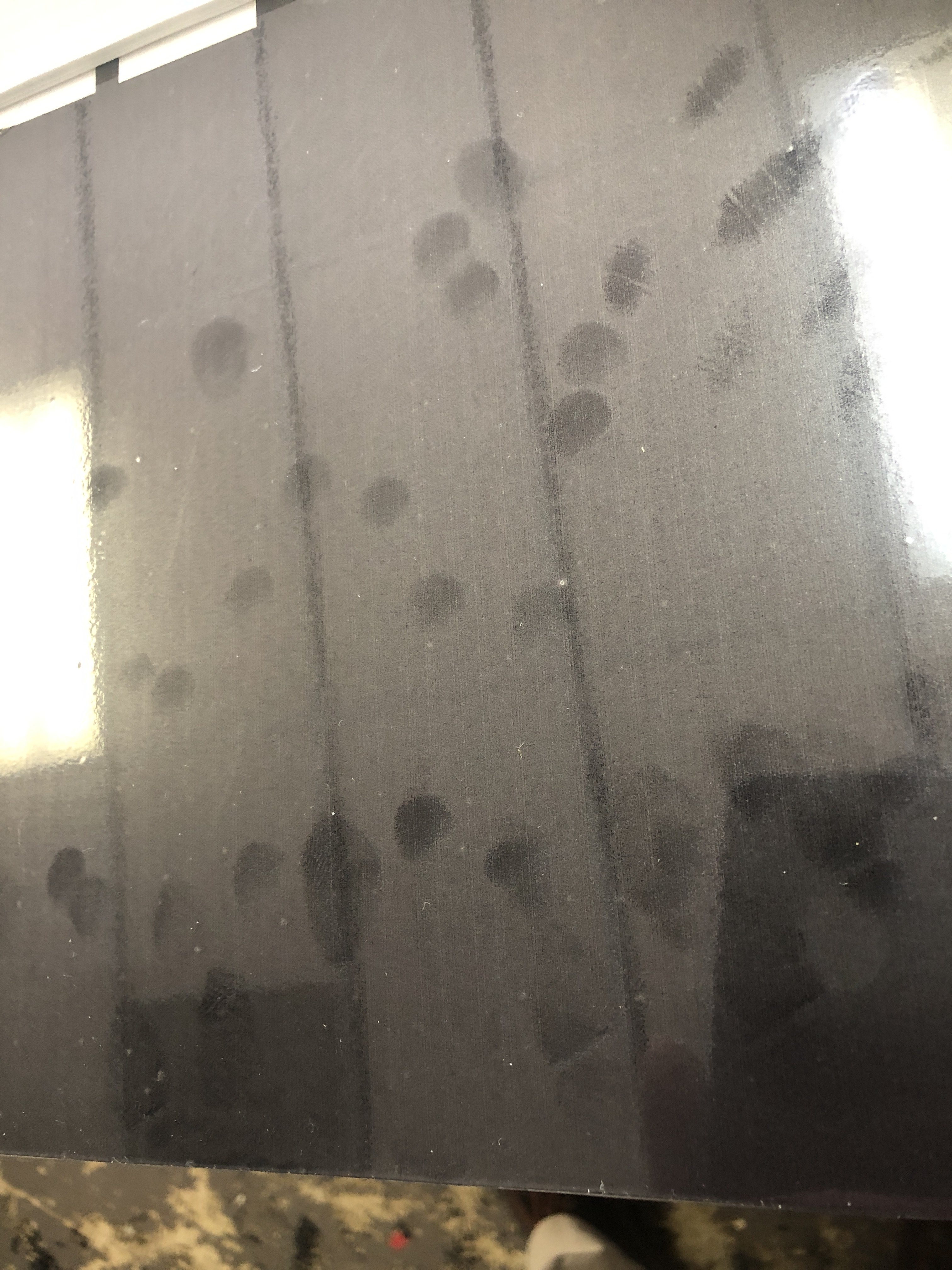

We have a GBC Professional 1064WF Cold Press Laminator. We have the calibration tool and we periodically adjust the pressure on one side or the other so that the pressure is equal. But recently it seems like the rollers aren't pushing down hard enough. I have attached a picture of a section of black ink on a 3mm ACM sign we printed on our HP550 flatbed printer and just laminated. When we laminated it, we ran the sign through our laminator on its tightest setting (fully closed - last notch - see second pic below) and the black ink appears dark grey. When our operator was wrapping the edges and trimming the excess laminate, his fingerprints are what is appearing in the picture. Wherever you press down hard, it gets darker - closer to black. The angle of the picture really makes it look bad, but when you first look at the sign, it looks fine. You don't notice a problem until you touch it. The lines you see are a reflection of the roof tiles, by the way. The fingerprints are the problem.

My first question is, should we be running it on the tightest setting when we are adding laminate to a 3mm sign? Our production guy says yes, but I'm not so sure.

Second question is, if we take off the end covers and tighten the pressure on both sides, is that going to resolve the issue? I'm hopeful it will, but I want to be SURE I'm not overlooking something obvious that could be causing this problem. I appreciate any input you may have.

My first question is, should we be running it on the tightest setting when we are adding laminate to a 3mm sign? Our production guy says yes, but I'm not so sure.

Second question is, if we take off the end covers and tighten the pressure on both sides, is that going to resolve the issue? I'm hopeful it will, but I want to be SURE I'm not overlooking something obvious that could be causing this problem. I appreciate any input you may have.