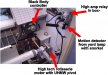

I have been using this homebrew for 3 years I think with nothing but a slip action to maintain the slack. I had plans to build

either a elect eye or mechanical means to turn it off and on but it was not necessary and I moved on. It and the IR heater

are triggered by a motion detector which switches on when the print carriage moves to print and turns off after 5-6 min of

inactivity. I did have to install a second rotisserie motor this summer tho. As an old **** I particularly enjoy the fact that I

don't have to work with the sometimes heavy roll of vinyl on the floor as with most winders.

I have the same take up reel the OP posted in the first post for my Roland sp540v printer, been using it for a year and it works great. It's a real time saver for all long prints, you can run unattended, it is a clutch based system and mine makes NO noise at all. Purchased on ebay for $320 with FREE shipping from Flordia seller, got it in a few days not like a month from China.

I do plan on making some kind of a sensor to shut off the motor so after printing so it doesn't run all night, I have been using a simple electrical timer, which you plug the take up reel motor cord into. I can set the timer for estimated time, like if the print time is estimated to be 2 hours, I set the timer for 3 hours, then after printing over night, the take up reel motor will shut off after 3 hours and not be on all night.

Gene@mpls: Nice job on your take up reel setup.

How does the motion detector work with the printed media?

I thought yard light motion detectors operated on body heat, the difference between the air temperature and then when a person walks buy at a different (body) temperature?

Does it sense the difference between printed and the non-printed area on the media?