-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making Your Own ICC Profile

- Thread starter buggyjr12

- Start date

If you want a reliable print process that faithfully reproduces color properly, you will

do your own calibration/media configuration and profiling. The reduction of wasted

test prints from 'tweaking it forever' will also be a good thing.

With Versaworks you will need the i1profiler Publish package, which includes the

spectrophotometer and i1profiler. If you want some automation of the scanning

process, you can get an i1io to physically move the spectro across the test charts,

or you can get an i1isis to read the test charts. The i1io will allow you to scan test

charts on materials that are up to 10mm thick. The i1isis can only scan test charts

typically printed on paper materials up to .45mm thick.

do your own calibration/media configuration and profiling. The reduction of wasted

test prints from 'tweaking it forever' will also be a good thing.

With Versaworks you will need the i1profiler Publish package, which includes the

spectrophotometer and i1profiler. If you want some automation of the scanning

process, you can get an i1io to physically move the spectro across the test charts,

or you can get an i1isis to read the test charts. The i1io will allow you to scan test

charts on materials that are up to 10mm thick. The i1isis can only scan test charts

typically printed on paper materials up to .45mm thick.

I'm running an SP-540V (don't laugh) so I'm not sure if it's even worth investing in a spectrophotometer.

I'm not necessarily worried about color matching per se, I'm just having trouble with banding at high-speed, saturation, etc.

My daily go to material is IJ35 or 3165GRA.

I just had my machine refurbished and it's printing better now than it has in a long time.

I've been using Roland's generic CWVR for years with satisfactory results, but I'd like to get my profile fine tuned now, too.

I'm not necessarily worried about color matching per se, I'm just having trouble with banding at high-speed, saturation, etc.

My daily go to material is IJ35 or 3165GRA.

I just had my machine refurbished and it's printing better now than it has in a long time.

I've been using Roland's generic CWVR for years with satisfactory results, but I'd like to get my profile fine tuned now, too.

I used to create ICC profiles for Onyx & Wasatch.

I don't have a i1 (eye one) anymore, but I have adjusted the ink limit in a prepackaged Versworks ICC profile, & that helped a lot.

I'm curious- why did you decide to stop making your own media configurations and profiles?

The Places I used manage the graphic department were large shops with several printers, the clients were all national chains (one shop we made the prototype signs for national chains)

& color consistency was critical. My wife and I have since move back to her home town & the job I have now is great, but my customers (mostly contractors) are just not that

concerned about colors & I have a good eye for manually adjusting... Plus I don't have an i1

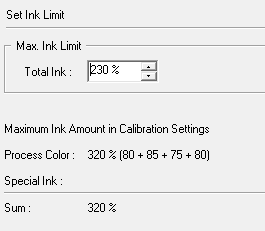

@buggyjr12 Not to beat a dead horse... Just a FYI, Those prepackaged ICC profiles are set for the make, model & material, but the ink limit is what adjust the ICC profile to your printer.

Print heads have mechanisms that slowly wear down, I used to up the voltage to heads as they got older to keep them consistent, but they have dumbed down printers, so adjusting the ink limits is your best bet.

Whoever created that profile was working on a new printer, 1st thing they did was set the ink limit & then printed their color spot to create the ICC profile.

Problem is, if someone with an older printer/print heads used that ICC Profile as is, their heads would be starved, so the profile making person will usually jack the ink limit back up (way too far IMHO) and send that profile out to the world... and that's why most people hate

the prepackaged profiles.

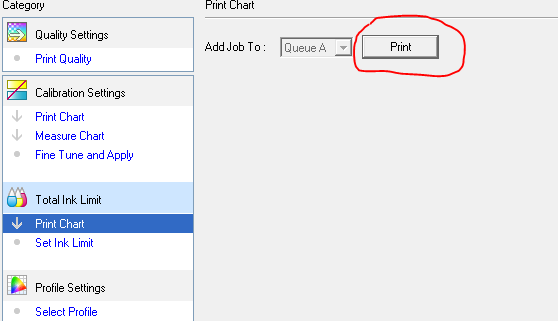

Before you go through the expense and time of creating your own profiles, I would suggest:

- In Versaworks, make a copy of your "Go-to" profile & name it something you will remember.

- In Versaworks, open up the copy and find the ink limit area, print the test, take a picture and post it here, and we will tell you what you're looking at.

It's easy, quick & will likely improve your colors and other issues you might be having.

& color consistency was critical. My wife and I have since move back to her home town & the job I have now is great, but my customers (mostly contractors) are just not that

concerned about colors & I have a good eye for manually adjusting... Plus I don't have an i1

@buggyjr12 Not to beat a dead horse... Just a FYI, Those prepackaged ICC profiles are set for the make, model & material, but the ink limit is what adjust the ICC profile to your printer.

Print heads have mechanisms that slowly wear down, I used to up the voltage to heads as they got older to keep them consistent, but they have dumbed down printers, so adjusting the ink limits is your best bet.

Whoever created that profile was working on a new printer, 1st thing they did was set the ink limit & then printed their color spot to create the ICC profile.

Problem is, if someone with an older printer/print heads used that ICC Profile as is, their heads would be starved, so the profile making person will usually jack the ink limit back up (way too far IMHO) and send that profile out to the world... and that's why most people hate

the prepackaged profiles.

Before you go through the expense and time of creating your own profiles, I would suggest:

- In Versaworks, make a copy of your "Go-to" profile & name it something you will remember.

- In Versaworks, open up the copy and find the ink limit area, print the test, take a picture and post it here, and we will tell you what you're looking at.

It's easy, quick & will likely improve your colors and other issues you might be having.

Pauly

Printrade.com.au

Every print shop should have colour management tools. But unfortunately a lot dont.

This usually shows the difference between a print shop who cares about their quality vs one that prints and sells with not as much QC.

Is it worth the investment in an i1pro? yes. get the i1pro3 publish pack. not only will it last you years, it'll improve the print quality you have.

This usually shows the difference between a print shop who cares about their quality vs one that prints and sells with not as much QC.

Is it worth the investment in an i1pro? yes. get the i1pro3 publish pack. not only will it last you years, it'll improve the print quality you have.

...adjusting the ink limits is your best bet.

Thanks for the help. I'll attach some pictures.

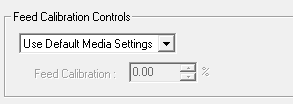

I already made a copy of the profile I've been using (CWVR) and tweaked the ink limits (default is 100%, 100%, 100%, 100%, total 220%), but when I push the total limit up closer to 300% or 350% (which is the default ink limit on 3651) I get oversaturation and puddling.

I could spend the rest of my life doing test prints with different profiles and making tweaks here and there, so that's why I was interested in making my own profile that's calibrated for my printer.

I see that the X-Rite machines are several thousand dollars and I certainly don't want to spend that to profile an SP-540V that probably isn't even able to take advantage of all the advantages of making your own profile. I was just hoping to get quickly get a sure-fire profile to get this thing printing to best of it's capabilities.

The banding in these pictures doesn't look quite as bad as it does in person for some reason.

To rule other stuff out, I just had my printer refurbished and the nozzle check is good, dampers are new, etc. I also just switched back to Roland OEM ink. I was using 20/20.

I even played with heat settings. I've been at 102, 102 for years, but I tried the default 98, 104 with no noticeable difference. I'm printing on IJ35C.

The file in the photos was printed on high speed. Printing in standard mode is WAY better, but still slightly noticeable to me. It seems to show up in reds and browns more so than blues and black.

Attachments

Are those lines horizontal as they come out of the machine? If so, they are what I have always called "Stepping". Putting down too much ink is making them more pronounced, but I don't think the cause.

As you said it could be too much heat, or you need to adjust your settings. I haven't had any issues with my Roland, so I'm not positive the best way of going about that.. This is where I would start;

Lower the heat as low as you can and the ink is still dry, and then adjust this:

Below is a screen capture of one of the profiles I adjusted, which was the same as yours, way too high (worse than too low IMHO)

Print your test here, and basically find the point where each color doesn't get darker and then add a little, so if the cyan line looks solid, vivid at 65% set your cyan ink limit to 70-75%

As you said it could be too much heat, or you need to adjust your settings. I haven't had any issues with my Roland, so I'm not positive the best way of going about that.. This is where I would start;

Lower the heat as low as you can and the ink is still dry, and then adjust this:

Below is a screen capture of one of the profiles I adjusted, which was the same as yours, way too high (worse than too low IMHO)

Print your test here, and basically find the point where each color doesn't get darker and then add a little, so if the cyan line looks solid, vivid at 65% set your cyan ink limit to 70-75%

Just get an i1 or i1pro2. From my experience, they produce comparable results. I recently sold my 15+ year old Rev A i1 for under $100 so they can be very cheap. The i1pro2 is a bit smoother, reads faster and nicer to operate but otherwise just getting a used i1 will already elevate your profiles.

The automated options, i1io and i1isis seems to be the biggest waste of money I can think of. I'd be interested if someone could make the case for these options outside of saving a bit of time on a handful of profiles.

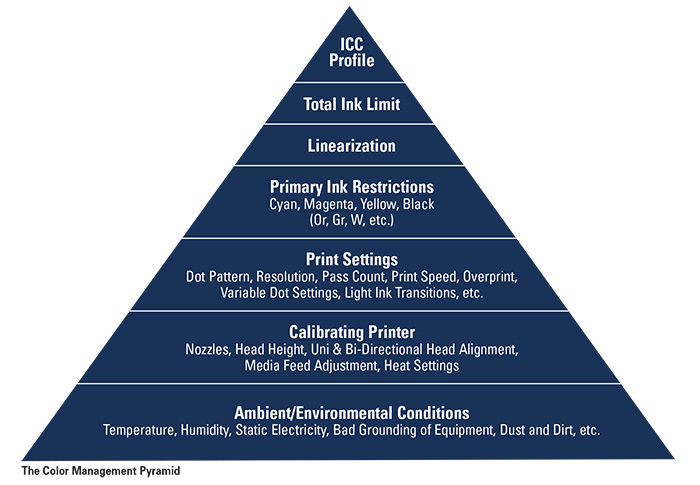

At least for UV printers, ink limits affect banding. Namely, too much ink can produce gloss banding or ink "combing". If you have your own device you can build profiles "from the ground up" as color management pyramid shows. If you alter anything below the ICC profile you are fundamentally invalidating your profile, since it is contingent on all the prior steps. You can get away with some things (using a Bi-directional profile to print Uni-Directional) but not others, such as changing ink limits, dot settings, transitions, etc. and get consistent results.

The main advantage of a spectrophotometer, beyond color accuracy, is the flexibility to explore your printer settings in full. Create multiple profiles with various settings and field test until you're satisfied.

The automated options, i1io and i1isis seems to be the biggest waste of money I can think of. I'd be interested if someone could make the case for these options outside of saving a bit of time on a handful of profiles.

At least for UV printers, ink limits affect banding. Namely, too much ink can produce gloss banding or ink "combing". If you have your own device you can build profiles "from the ground up" as color management pyramid shows. If you alter anything below the ICC profile you are fundamentally invalidating your profile, since it is contingent on all the prior steps. You can get away with some things (using a Bi-directional profile to print Uni-Directional) but not others, such as changing ink limits, dot settings, transitions, etc. and get consistent results.

The main advantage of a spectrophotometer, beyond color accuracy, is the flexibility to explore your printer settings in full. Create multiple profiles with various settings and field test until you're satisfied.

I agree with everything you said, but wanted to point out; if you choose to download and use a ICC profile, you need to adjust the ink limit to your printer, that's what tunes it in and makes the rest of the profile correct.If you alter anything below the ICC profile you are fundamentally invalidating your profile, since it is contingent on all the prior steps.

Whoever created that profile, 1st thing they did was set the ink limit to that printer, then created the ICC profile.

Problem is, before they send that profile out for people to download, they jack the ink profile back up to a level that will work for most printers.

Last edited:

Pauly

Printrade.com.au

The automated options, i1io and i1isis seems to be the biggest waste of money I can think of. I'd be interested if someone could make the case for these options outside of saving a bit of time on a handful of profiles.

View attachment 153012

Many reasons i'd have a automated spectro VS a hand held with a ruler.

Accuracy & Speed are the main 2.

Especially if you're working with a new media and may have to make a few profiles before you're happy. it saves a lot of time.

I use a Barbieri LFP RT s3 and a barbieri Spectropad s2.

90% of the time i'll use the LFP to read ICC patch sets.

if it's a linearization or ink limits, i'll leave that to the spectropad as it's easier and quicker as it's only 4-6 lines to read.

When i do a data analysation of patch readings from the spectropad vs LFP, the LFP is always more accurate.

Just get an i1 or i1pro2.

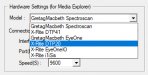

What about a DTP41 or DTP20? I don't see i1 or i1pro2 in my drop-down list.