Hi there,

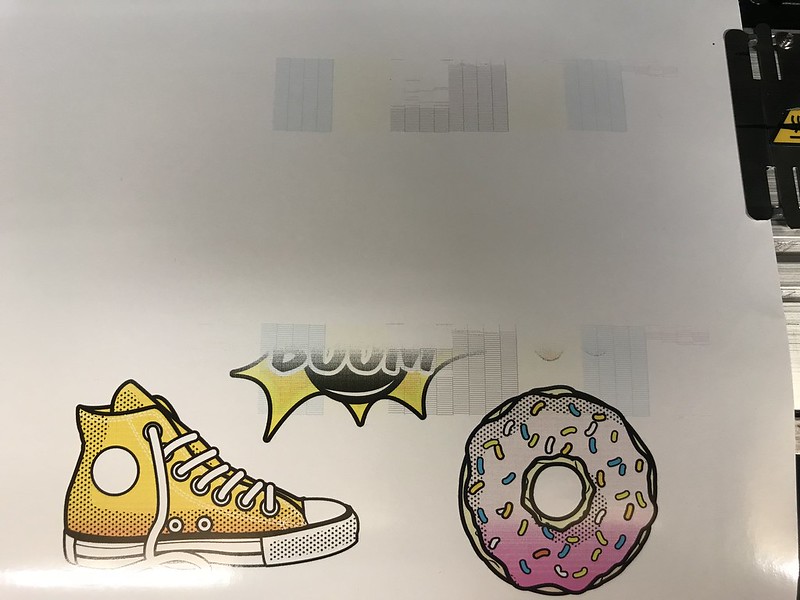

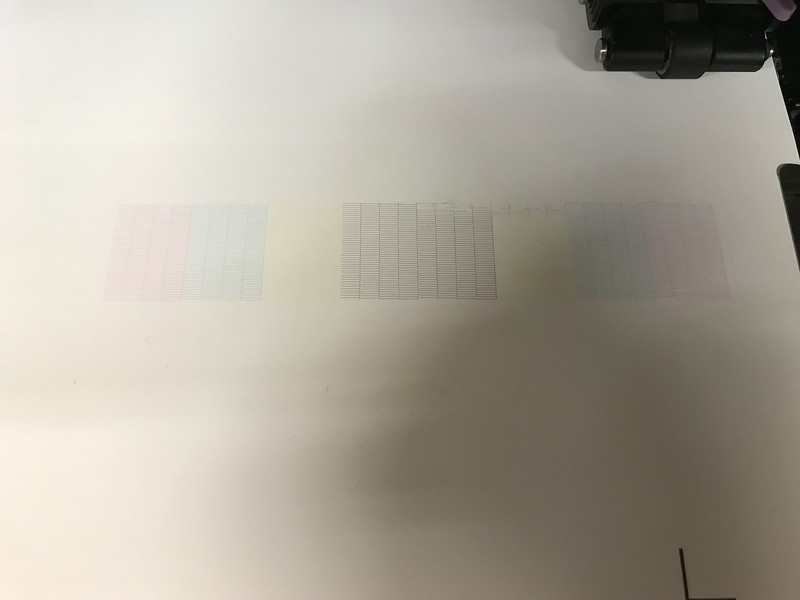

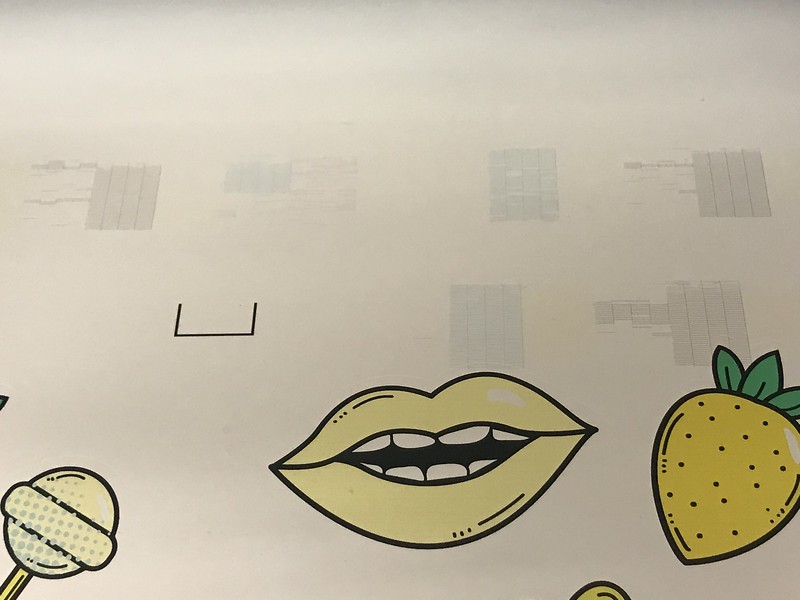

Just yesterday I changed all 8 dampers on my Mimaki CJV30-100 with cheap Chinese dampers (complete with O-ring and screwcap). I bought the machine second hand and have the machine for 1,5 year now, so probably about time. Hoped it would solve some of the banding I can't seem to get rid of.

Everything went well, looks ok after visual inspection. No leakage and the dampers fill up to about 1/3 after I run the "fill ink" menu option.

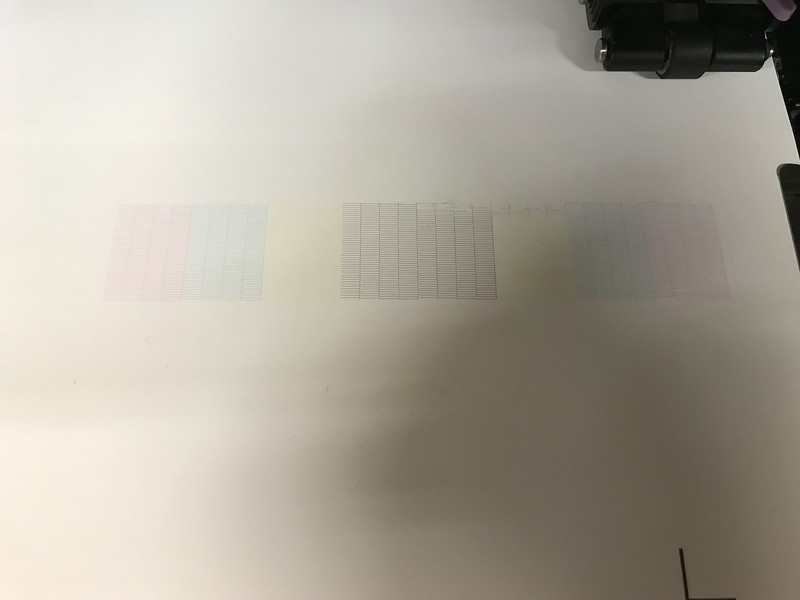

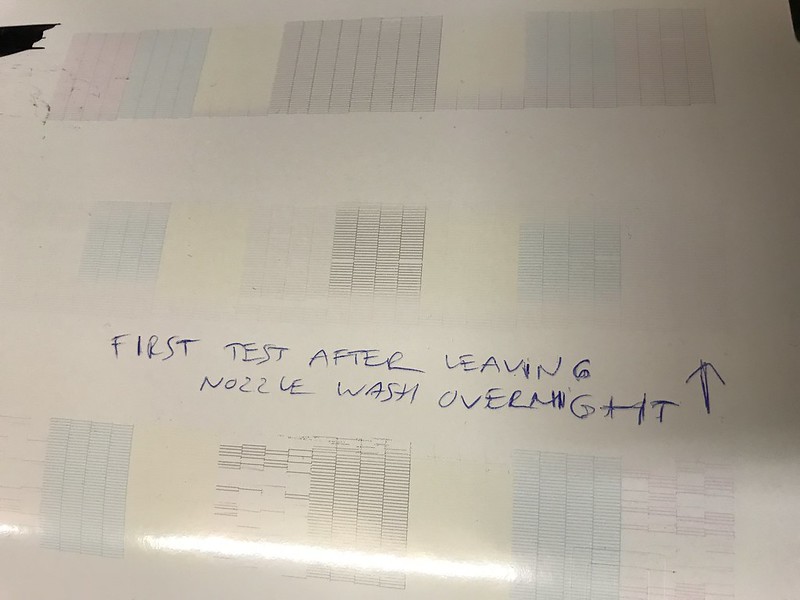

Initial testprint was fine after a nozzle wash and hard clean. And the banding was almost gone completely at 12 pass bi-directional. So it looked like a succes.

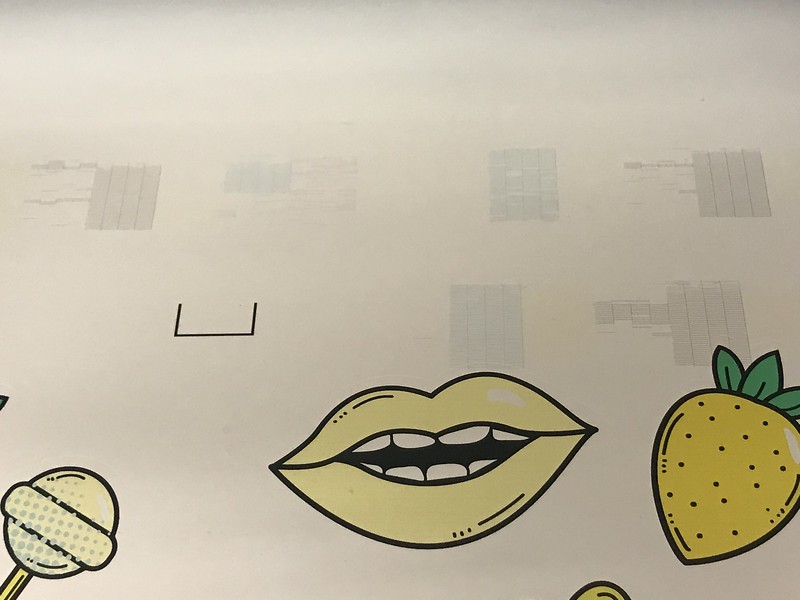

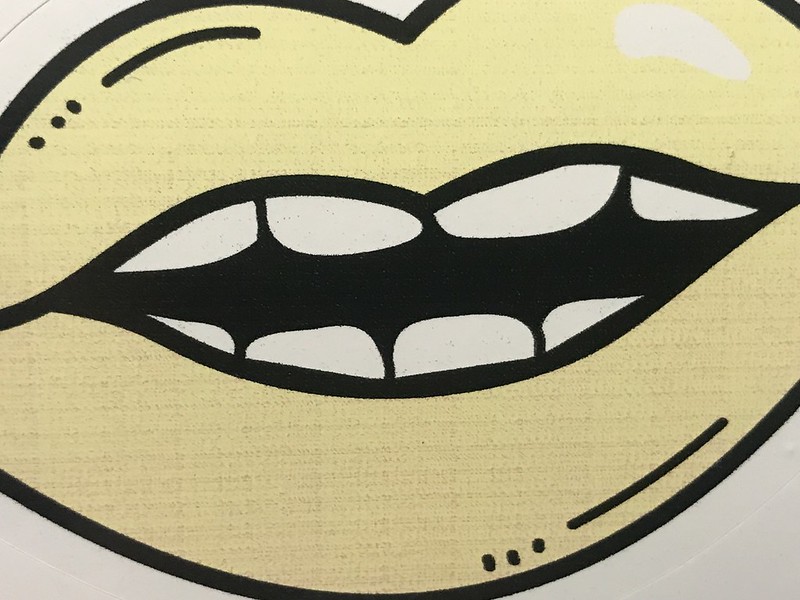

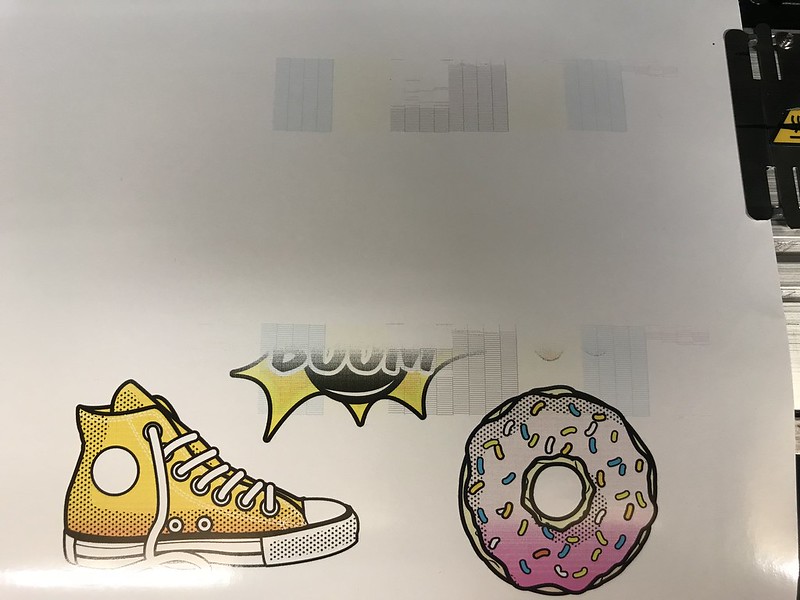

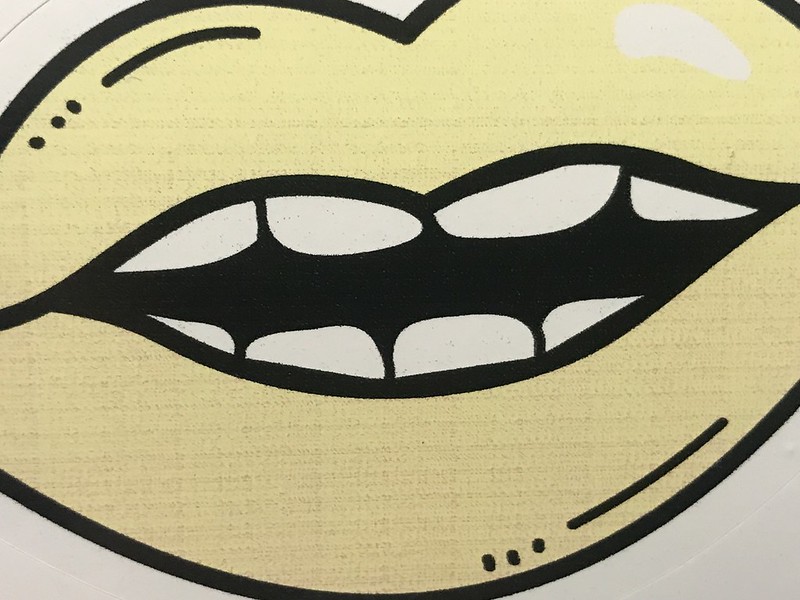

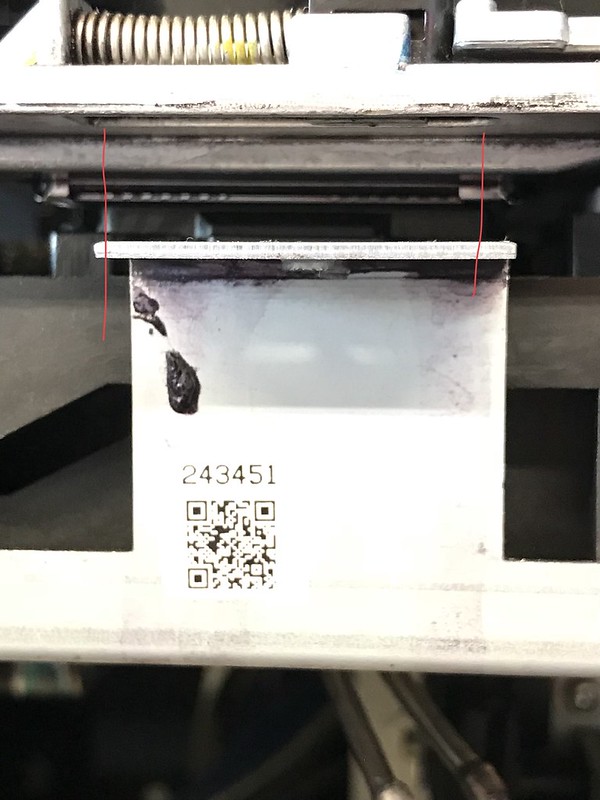

But now, a day later, I am printing small batches of stickers and some of my colors completely disappear during print!

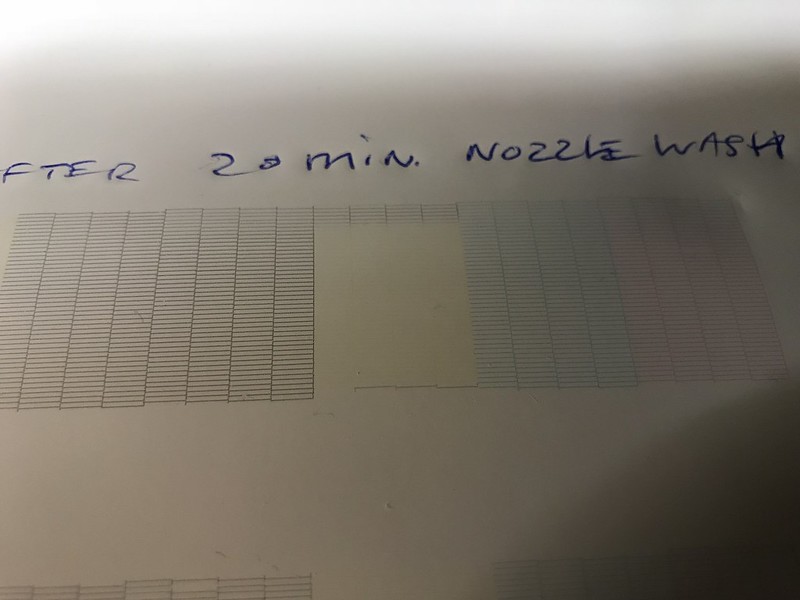

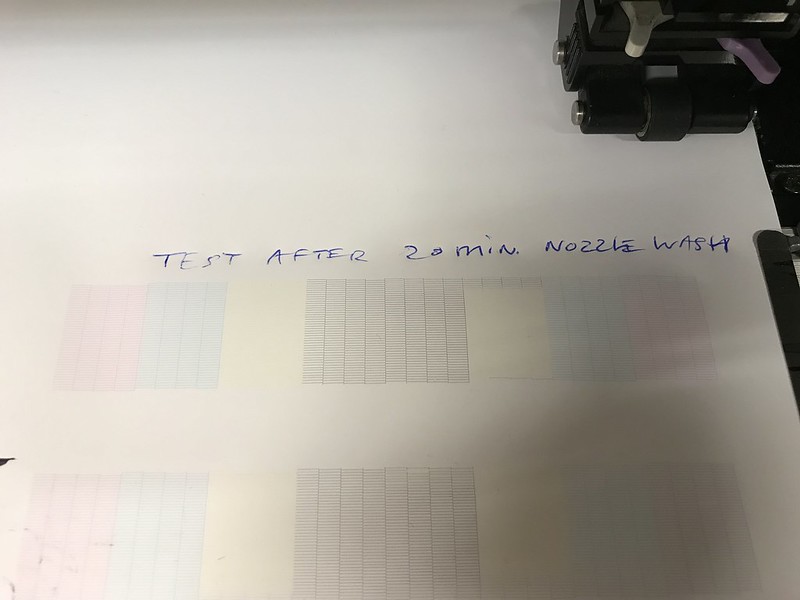

Mostly magenta but other colors too. Can get most of them back after a couple of cleaning cycles (hard cleaning and nozzle wash 20 min) but this shouldn't be happening.

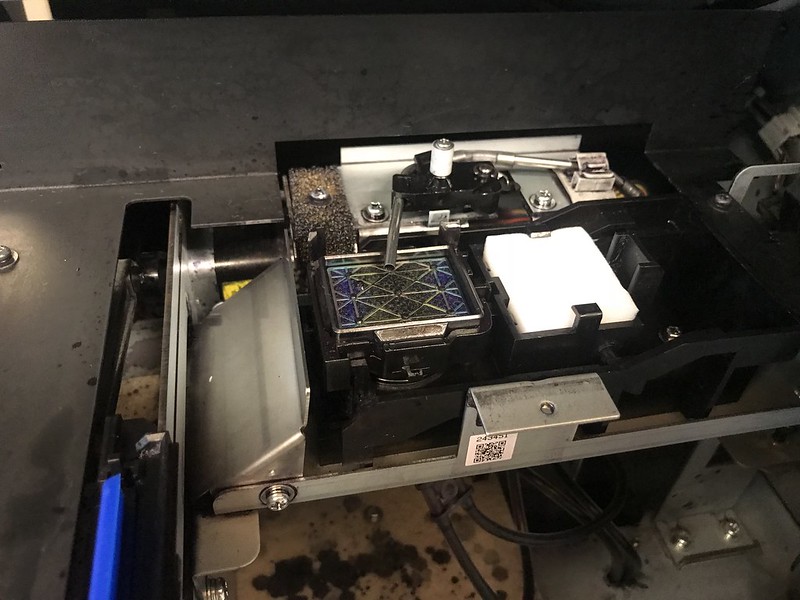

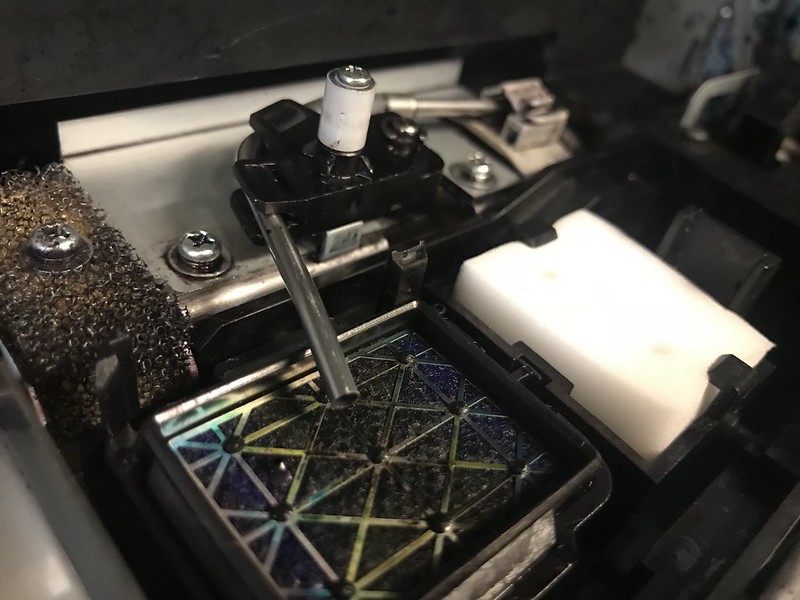

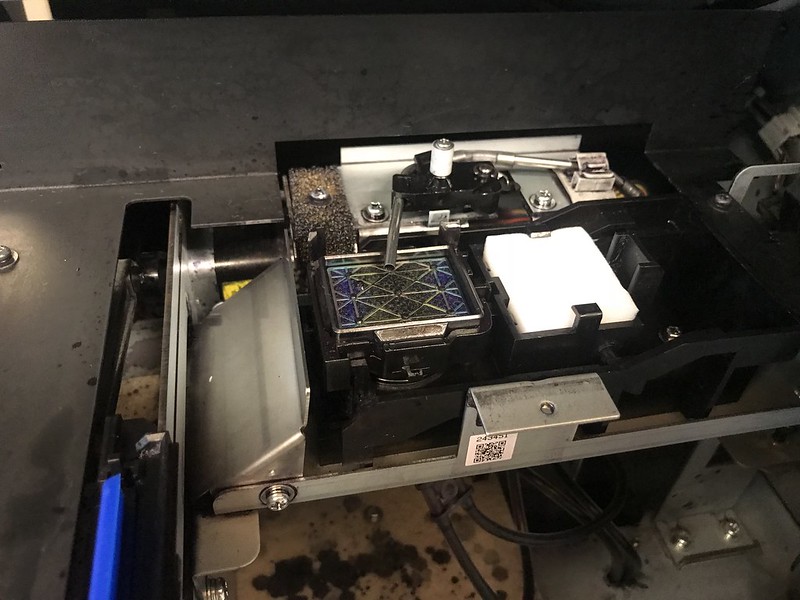

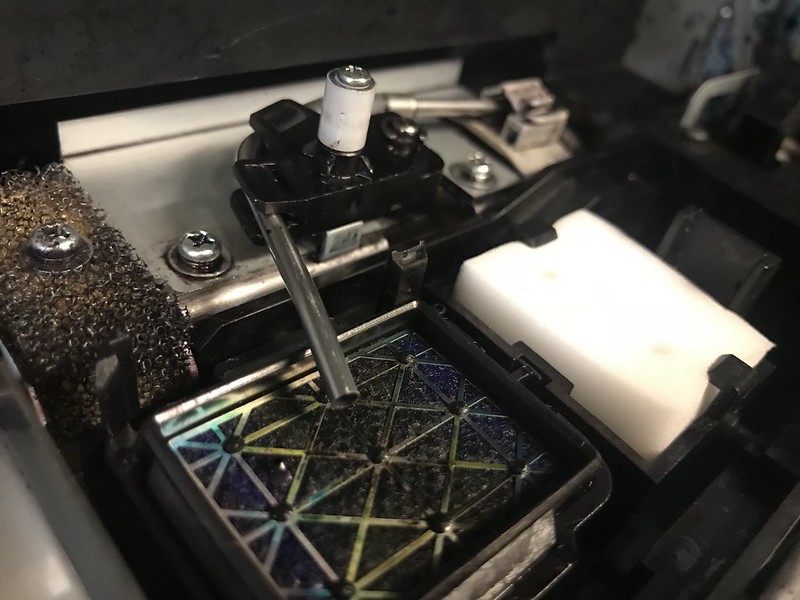

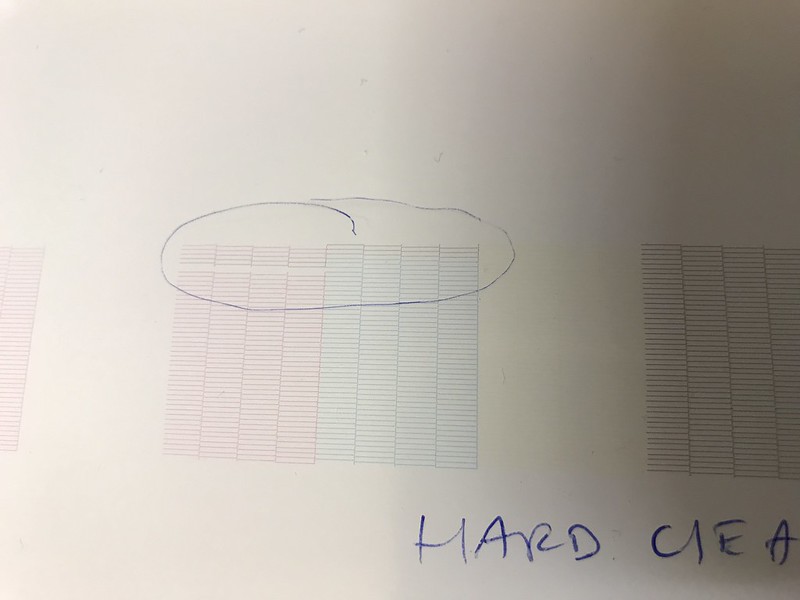

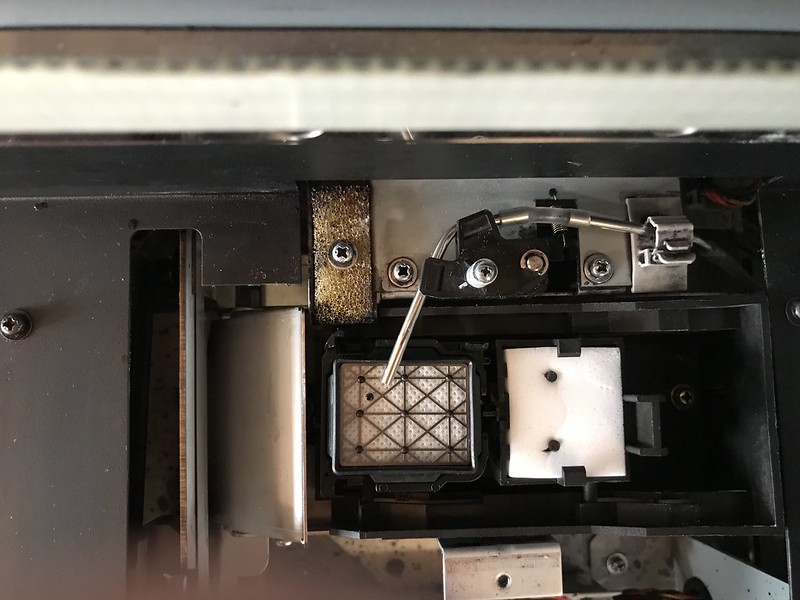

Is there something wrong with the dampers or the capping station? Cap top is about 6 months old.

And noticed the capping station got soaked with ink, cleaned it completely tonight -like brand new-, but after a small sticker run it was wet of ink again. Pump was changed 6 months ago.

Thanks for reading!

IMG_7428 by barrybuise, on Flickr

IMG_7428 by barrybuise, on Flickr

IMG_7429 by barrybuise, on Flickr

IMG_7429 by barrybuise, on Flickr

IMG_7427 by barrybuise, on Flickr

IMG_7427 by barrybuise, on Flickr

IMG_7422 by barrybuise, on Flickr

IMG_7422 by barrybuise, on Flickr

IMG_7424 by barrybuise, on Flickr

IMG_7424 by barrybuise, on Flickr

IMG_7425 by barrybuise, on Flickr

IMG_7425 by barrybuise, on Flickr

IMG_7421 by barrybuise, on Flickr

IMG_7421 by barrybuise, on Flickr

IMG_7417 by barrybuise, on Flickr

IMG_7417 by barrybuise, on Flickr

IMG_7416 by barrybuise, on Flickr

IMG_7416 by barrybuise, on Flickr

IMG_7415 by barrybuise, on Flickr

IMG_7415 by barrybuise, on Flickr

IMG_7414 by barrybuise, on Flickr

IMG_7414 by barrybuise, on Flickr

Just yesterday I changed all 8 dampers on my Mimaki CJV30-100 with cheap Chinese dampers (complete with O-ring and screwcap). I bought the machine second hand and have the machine for 1,5 year now, so probably about time. Hoped it would solve some of the banding I can't seem to get rid of.

Everything went well, looks ok after visual inspection. No leakage and the dampers fill up to about 1/3 after I run the "fill ink" menu option.

Initial testprint was fine after a nozzle wash and hard clean. And the banding was almost gone completely at 12 pass bi-directional. So it looked like a succes.

But now, a day later, I am printing small batches of stickers and some of my colors completely disappear during print!

Mostly magenta but other colors too. Can get most of them back after a couple of cleaning cycles (hard cleaning and nozzle wash 20 min) but this shouldn't be happening.

Is there something wrong with the dampers or the capping station? Cap top is about 6 months old.

And noticed the capping station got soaked with ink, cleaned it completely tonight -like brand new-, but after a small sticker run it was wet of ink again. Pump was changed 6 months ago.

Thanks for reading!

IMG_7428 by barrybuise, on Flickr

IMG_7428 by barrybuise, on Flickr IMG_7429 by barrybuise, on Flickr

IMG_7429 by barrybuise, on Flickr IMG_7427 by barrybuise, on Flickr

IMG_7427 by barrybuise, on Flickr IMG_7422 by barrybuise, on Flickr

IMG_7422 by barrybuise, on Flickr IMG_7424 by barrybuise, on Flickr

IMG_7424 by barrybuise, on Flickr IMG_7425 by barrybuise, on Flickr

IMG_7425 by barrybuise, on Flickr IMG_7421 by barrybuise, on Flickr

IMG_7421 by barrybuise, on Flickr IMG_7417 by barrybuise, on Flickr

IMG_7417 by barrybuise, on Flickr IMG_7416 by barrybuise, on Flickr

IMG_7416 by barrybuise, on Flickr IMG_7415 by barrybuise, on Flickr

IMG_7415 by barrybuise, on Flickr IMG_7414 by barrybuise, on Flickr

IMG_7414 by barrybuise, on Flickr

IMG_7460

IMG_7460 IMG_7461

IMG_7461 IMG_7463

IMG_7463 IMG_7459

IMG_7459 IMG_7462

IMG_7462 IMG_7457

IMG_7457 Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled