awalracing

New Member

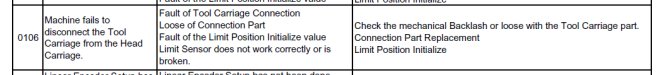

Looking for any help or suggestions you may have? At my wits end! A few days ago my XC540 was just finishing a job and it was going to park. It made a clunk nose and beeped. The code 0106. After googling it, it said to do a Limit initialization. So I did this by pressing and holding left, up, right then power. Got through that and it started printing off to one side after laying down it's initial passes. (It's almost like the 1st half of the print head print perfect, then the next half is pushed to the side a bit.) Thinking it might be the encoder strip or sensor, I cleaned them and tried again. Same thing! So I went ahead and change the encoder strip, still didn't work. After talking to a few people, I was advised to make a detailed post. So hear we are. Here are a few test prints. #1 In the service menu, print menu, Horizontal test It finishes the print and says "set head hight to high" with a beep then won't let me back to any menus without shutting it down. Small writing seems blurred on DT3 #2 Service, print, bidirectional test It finishes the print and says "set head hight to high" with a beep then won't let me back to any menus without shutting it down Small writing seems blurred on DT3 but better then #1 and boxes look way off. #3 Service, print, fill test Then went back and parked properly. Allowing me to use buttons and menus again. Test looks good other then the color edges are shifted. Cyan, magenta, black seem to be affected. Yellow, LCyan and Lmegenta look unaffected. Although it doesn't look like a color issue, it looks like it shifts out then in again. Video to follow. #4 Service, print, bi-directional check Then went back and parked properly. Allowing me to use buttons and menus again. All lines look really good other then the very look like it's missing a few. The other is about 11" from the start and there bunched up. #5 showing how lettering is starts good, then shifts off. #6 Your typical test print. First half is good, second half shifts off. I was advised to clean the encoder strip and sensor, after doing so it seemed to get worse. i will post more photos in the comments below as i can only upload 5. last night i when to bed very frustrated, could get anywhere with this thing.

I woke up this morning with positive vibes and wanting Roly to work more then anything in the world! To my disappointment, I started a test print and my Light Cyan is streaking everywhere. (photos in comments) it only seems to be getting worse. Im avery small bussiness and with out this machine running we have no income. So PLEASE Anything else you might need to know, shoot me a message. I'll be around the printer until it's up and running again. Thank in advance.

I woke up this morning with positive vibes and wanting Roly to work more then anything in the world! To my disappointment, I started a test print and my Light Cyan is streaking everywhere. (photos in comments) it only seems to be getting worse. Im avery small bussiness and with out this machine running we have no income. So PLEASE Anything else you might need to know, shoot me a message. I'll be around the printer until it's up and running again. Thank in advance.

Attachments

-

448622077_7810180775740539_8273587416602212350_n.jpg147.8 KB · Views: 167

448622077_7810180775740539_8273587416602212350_n.jpg147.8 KB · Views: 167 -

448873740_343657471950120_4186777575314341776_n.jpg149 KB · Views: 101

448873740_343657471950120_4186777575314341776_n.jpg149 KB · Views: 101 -

448716681_465141472798566_7212657798424730909_n.jpg154.2 KB · Views: 89

448716681_465141472798566_7212657798424730909_n.jpg154.2 KB · Views: 89 -

448745691_1498462447712944_5920066288002690117_n.jpg120.4 KB · Views: 95

448745691_1498462447712944_5920066288002690117_n.jpg120.4 KB · Views: 95 -

448711068_1245823103491712_1140656940111812863_n.jpg144 KB · Views: 96

448711068_1245823103491712_1140656940111812863_n.jpg144 KB · Views: 96