Hi All…

My name is Uriyah (ubeny) and I live in Fayetteville, GA. I have a good bit of knowledge with aqueous printing as I do a fair amount of fine art stuff when I can but I have virtually no experience with eco solvent printing nor what it takes to maintain the printers. I happened up on this wonderful site a few weeks ago while doing some research for possible fixes for a Mutoh VJ 1204 I purchased from someone who was upgrading. Again, I had absolutely no knowledge when I found this site but I can now say that, with the super knowledge so many of you graciously give here, I’m in a much better place understanding what I have and what I have to do… so Thank You!!!

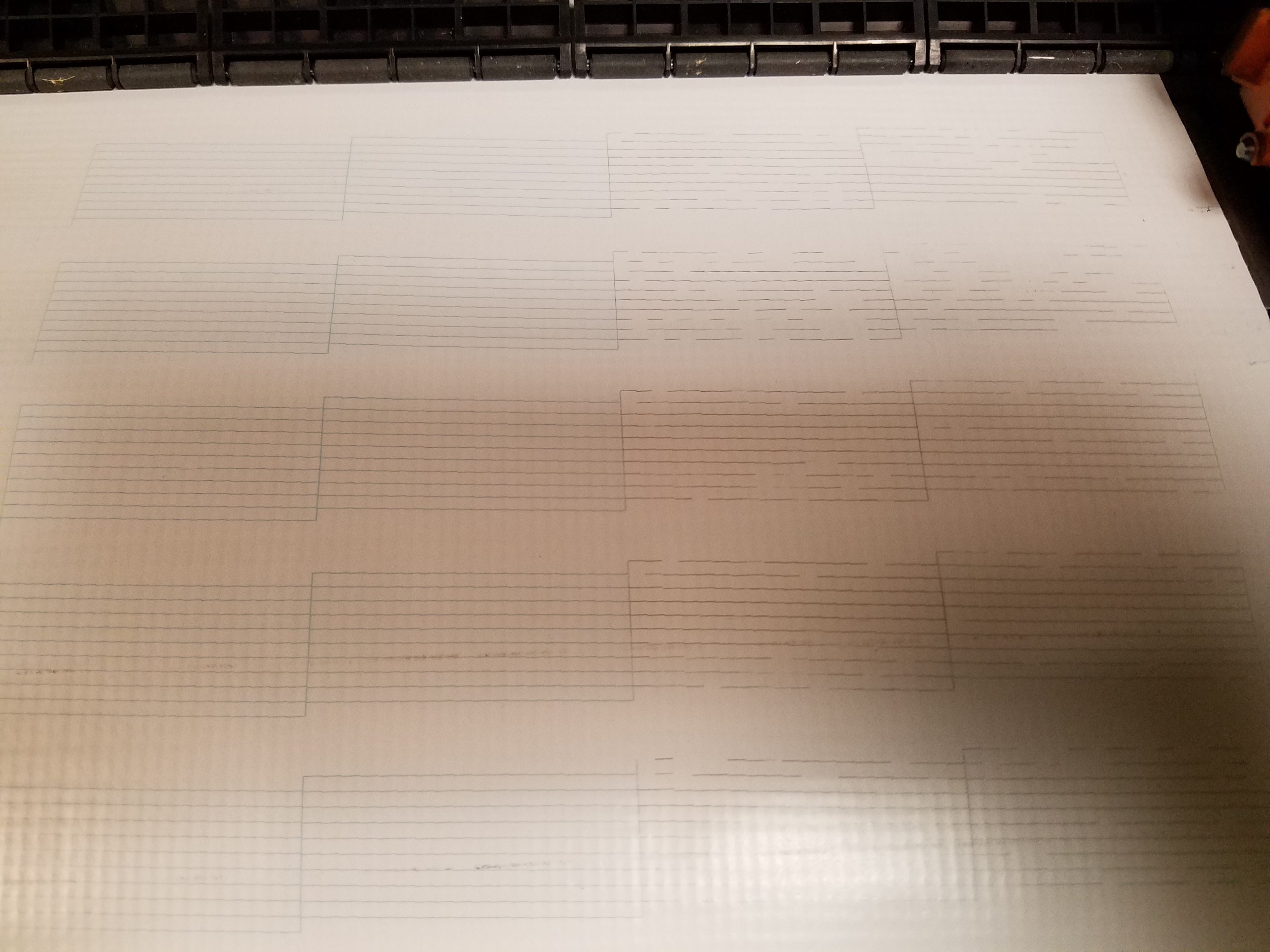

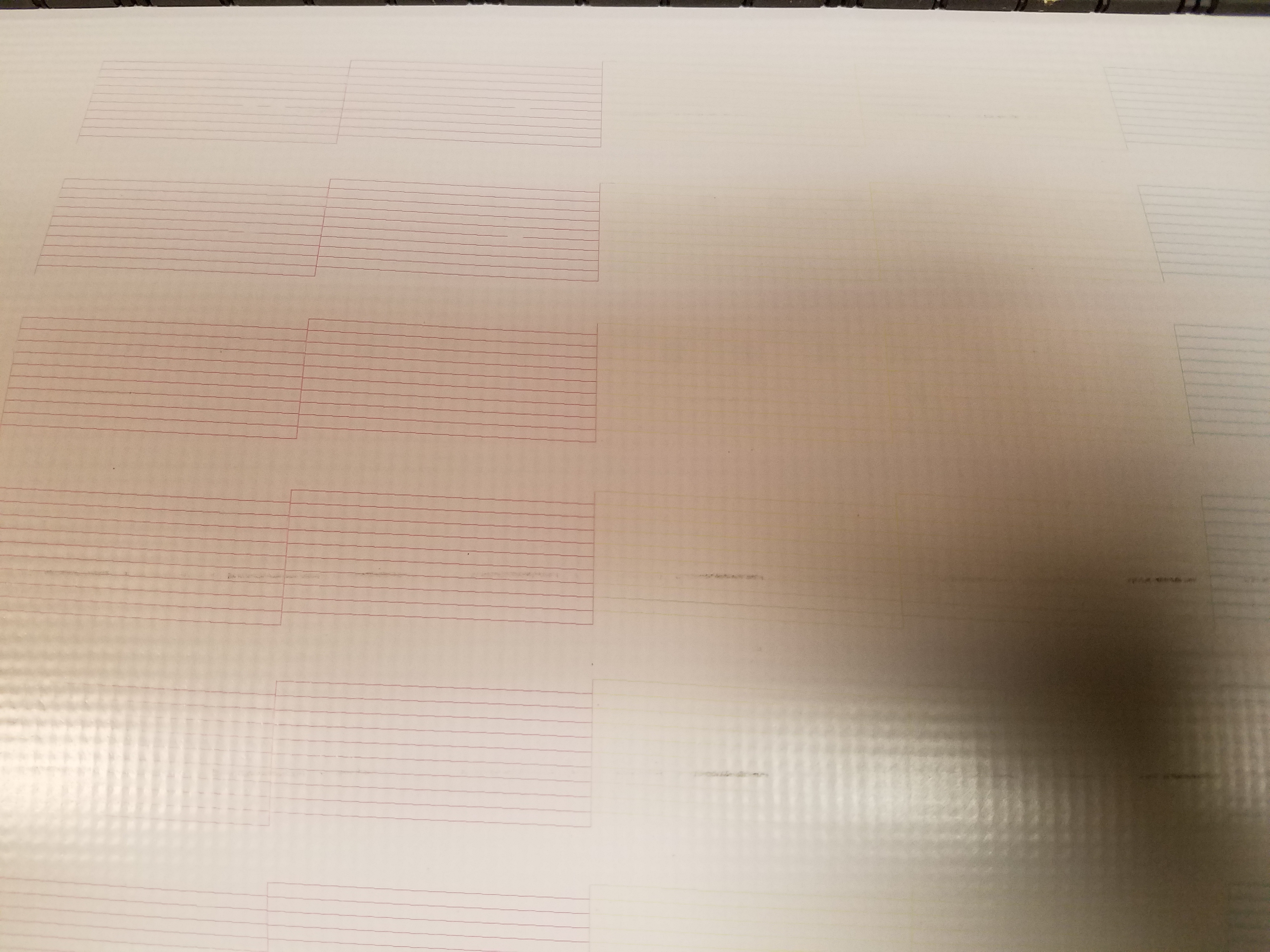

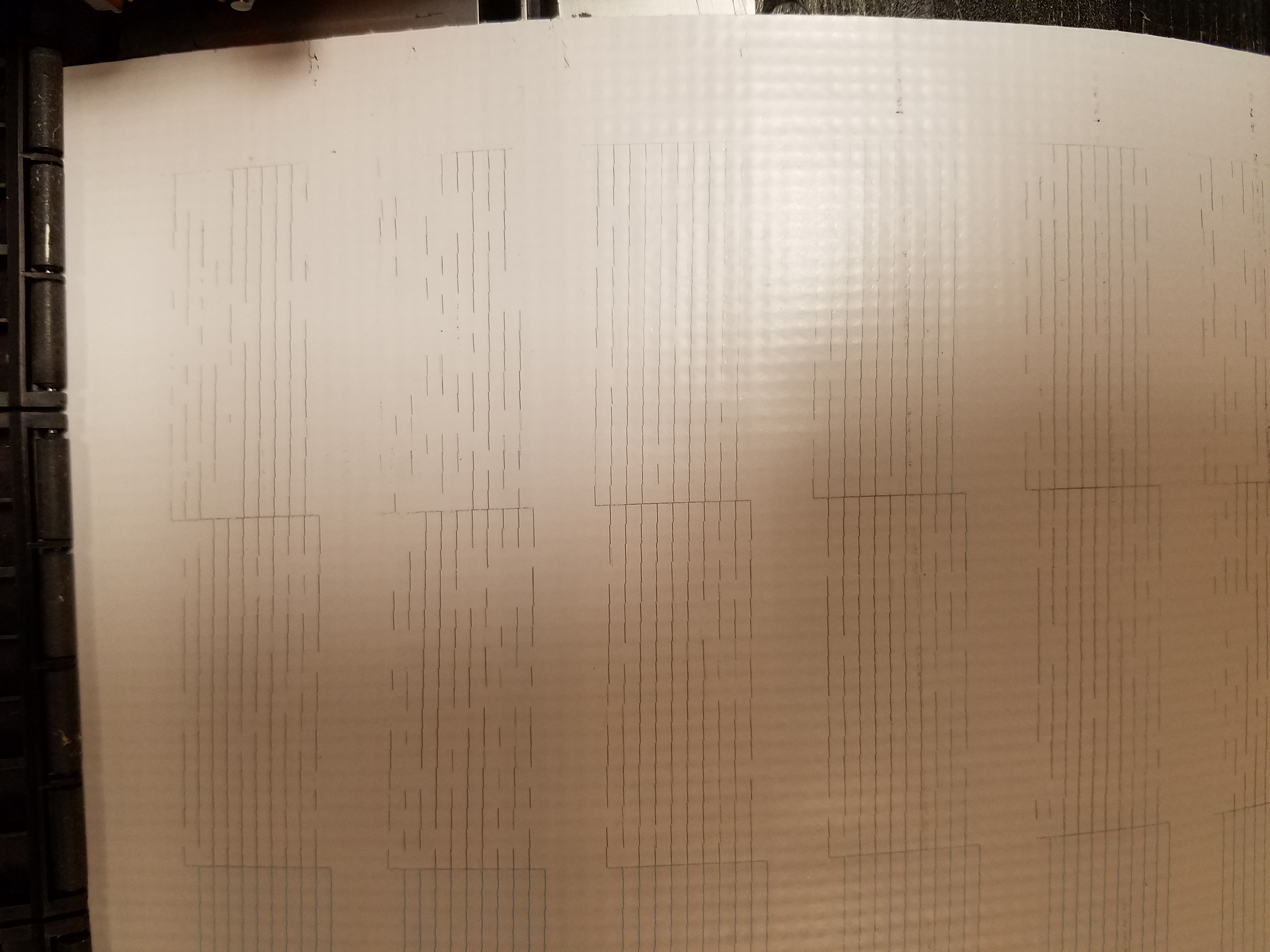

Fast forward a bit… so while I still have not gotten the VJ 1204 to print properly, (largely due to not having much time… I currently have a day job as an IT manager) 2 weeks ago I got a pretty good deal on a VJ 1324 that the owner said he was told had a “printhead issue”. It actually prints very well… except for the black. The nozzle check is puzzling to me (please remember very limited knowledge here). The magenta, cyan and yellow consistently produces perfect nozzle checks, but with the black, who knows what will show up. Often, I can perform a check with poor results, do a long cleaning and the results are even worse! Other times I can perform a check after it has sat a bit and get a much better result without even cleaning. Meanwhile, the other 3 colors are still perfect.

Any ideas please?

Again, Thanks so much! I’m really enjoying this new experience and think I might look at this as a real business venture!

-ubeny

My name is Uriyah (ubeny) and I live in Fayetteville, GA. I have a good bit of knowledge with aqueous printing as I do a fair amount of fine art stuff when I can but I have virtually no experience with eco solvent printing nor what it takes to maintain the printers. I happened up on this wonderful site a few weeks ago while doing some research for possible fixes for a Mutoh VJ 1204 I purchased from someone who was upgrading. Again, I had absolutely no knowledge when I found this site but I can now say that, with the super knowledge so many of you graciously give here, I’m in a much better place understanding what I have and what I have to do… so Thank You!!!

Fast forward a bit… so while I still have not gotten the VJ 1204 to print properly, (largely due to not having much time… I currently have a day job as an IT manager) 2 weeks ago I got a pretty good deal on a VJ 1324 that the owner said he was told had a “printhead issue”. It actually prints very well… except for the black. The nozzle check is puzzling to me (please remember very limited knowledge here). The magenta, cyan and yellow consistently produces perfect nozzle checks, but with the black, who knows what will show up. Often, I can perform a check with poor results, do a long cleaning and the results are even worse! Other times I can perform a check after it has sat a bit and get a much better result without even cleaning. Meanwhile, the other 3 colors are still perfect.

Any ideas please?

Again, Thanks so much! I’m really enjoying this new experience and think I might look at this as a real business venture!

-ubeny