Hey gang,

I have been lurking for a while but have tried to learn rather than annoy.

Our JFX200 has a weird issue that I would love some advice on.

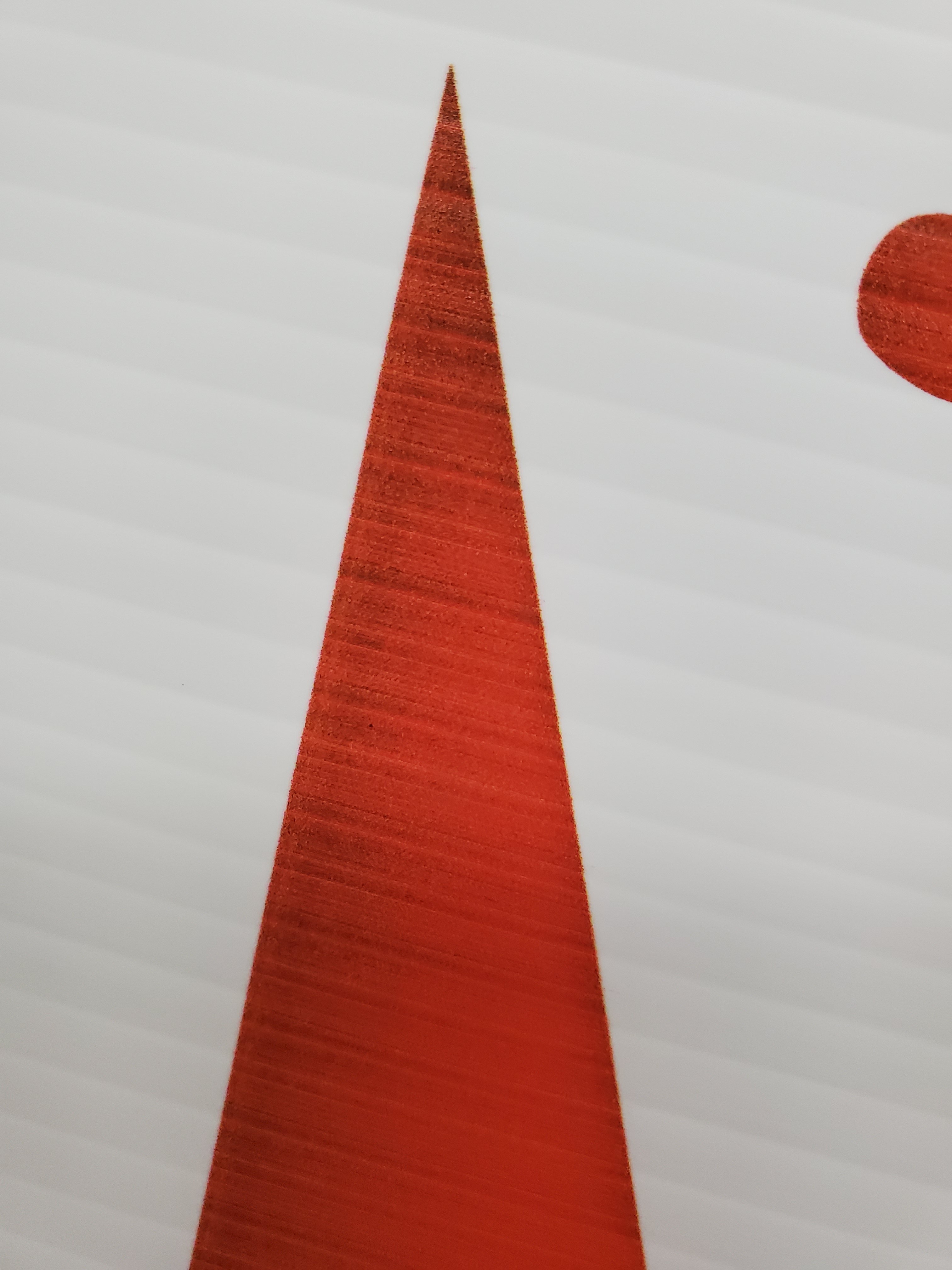

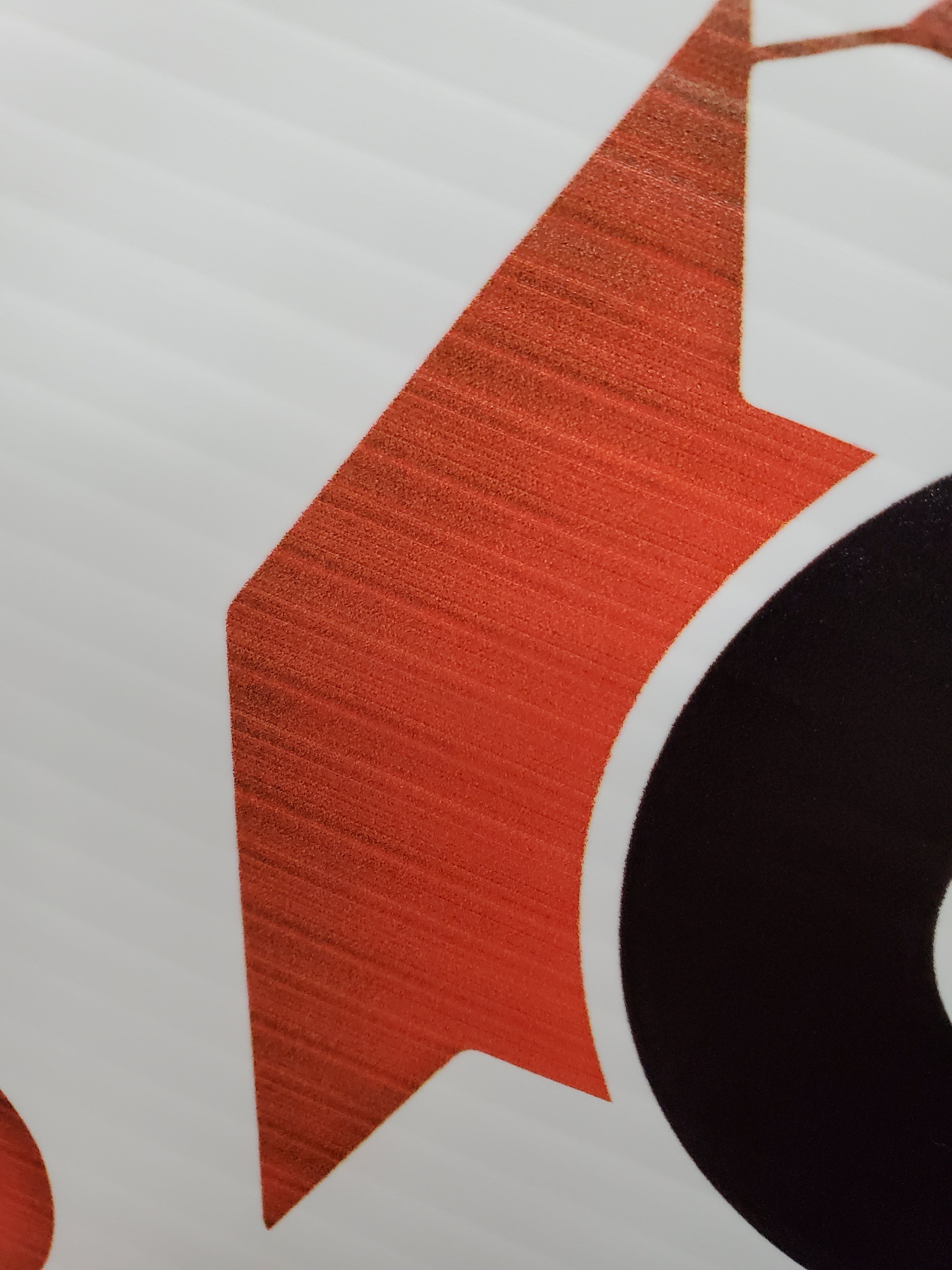

When we print red toward the end of the pass we get this odd gradient where it seems to revert to black. It does it no matter the scan length. We have had this machine for a while now and it finally seems to be coming into it's own and making us a few bucks.

I would love to call in someone to fix it but Judging from the install and 1 under warranty once over our Ricoh guys don't know this machine. I understand service comes with a bill but I hate paying to have a guy come in and train by phone.

Any advice would be greatly appreciated!

Frank

I have been lurking for a while but have tried to learn rather than annoy.

Our JFX200 has a weird issue that I would love some advice on.

When we print red toward the end of the pass we get this odd gradient where it seems to revert to black. It does it no matter the scan length. We have had this machine for a while now and it finally seems to be coming into it's own and making us a few bucks.

I would love to call in someone to fix it but Judging from the install and 1 under warranty once over our Ricoh guys don't know this machine. I understand service comes with a bill but I hate paying to have a guy come in and train by phone.

Any advice would be greatly appreciated!

Frank