Pat Whatley

New Member

Most of the kids in my family go to a small private school in the country. It's the kind of place that holds "FAMILY WORK DAY" a couple of times a year to do maintenance projects at the school and the whole community shows up.

They've got an idea to do something a little different with athletic sponsor signs. Instead of the usual sign stuck to the fence they want to do smaller signs on the side of the road that leads from the entrance to the school to the athletic fields and gym in the back of the campus.

Of course the budget for said project is basically nothing which is fine, I'm perfectly willing to donate the original set ups for this.

I don't want to use wood posts because I'm having a horrible time getting good posts right now. Even 10' posts are twisting ridiculously. I priced out steel and aluminum posts but both of those are going to run me close to $100 each. I want to use something that looks a little better than street sign posts.

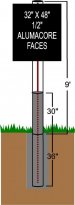

Enter my idea, and before you think I just pulled this out of my ass there's actually been a lot of thought and research involved. I want to take 12' pieces of 4" diameter schedule 40 PVC pipe and use them as posts (I can get the PVC donated). Since I don't think the PVC on its own will hold up my idea is to dig 8" diameter holes (auger bit size) 36" deep, set the PVC in concrete and let it set up. Then put a 1/2" x 12' piece of rebar inside the PVC and pour concrete into the pipe in stages until the pipe is filled.

The signs are going to be 32" x 48" reclaimed Alumacore panels with digital prints, the posts eventually painted in the school color.

So my question is does anybody see a realistic reason why this won't work? Am I missing something blatantly obvious? Is is really going to be necessary to fill the pipes all the way or do you think halfway up will work?

If you're thinking the concrete is going to expand and crack the PVC I've never had that problem with the ballasts I've made using 6" x 48" PVC with end caps on each end. Would 4" behave that much differently? I can also fill the PVC with polyurethane foam instead of concrete if that sounds like a better idea.

They've got an idea to do something a little different with athletic sponsor signs. Instead of the usual sign stuck to the fence they want to do smaller signs on the side of the road that leads from the entrance to the school to the athletic fields and gym in the back of the campus.

Of course the budget for said project is basically nothing which is fine, I'm perfectly willing to donate the original set ups for this.

I don't want to use wood posts because I'm having a horrible time getting good posts right now. Even 10' posts are twisting ridiculously. I priced out steel and aluminum posts but both of those are going to run me close to $100 each. I want to use something that looks a little better than street sign posts.

Enter my idea, and before you think I just pulled this out of my ass there's actually been a lot of thought and research involved. I want to take 12' pieces of 4" diameter schedule 40 PVC pipe and use them as posts (I can get the PVC donated). Since I don't think the PVC on its own will hold up my idea is to dig 8" diameter holes (auger bit size) 36" deep, set the PVC in concrete and let it set up. Then put a 1/2" x 12' piece of rebar inside the PVC and pour concrete into the pipe in stages until the pipe is filled.

The signs are going to be 32" x 48" reclaimed Alumacore panels with digital prints, the posts eventually painted in the school color.

So my question is does anybody see a realistic reason why this won't work? Am I missing something blatantly obvious? Is is really going to be necessary to fill the pipes all the way or do you think halfway up will work?

If you're thinking the concrete is going to expand and crack the PVC I've never had that problem with the ballasts I've made using 6" x 48" PVC with end caps on each end. Would 4" behave that much differently? I can also fill the PVC with polyurethane foam instead of concrete if that sounds like a better idea.