myront

Dammit, make it faster!!

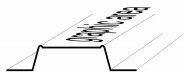

Having a hard time as a designer explaining the necessary specs needed for panceface signs. "Retainer, flange, and/or rise" means nothing to the designer. We keep getting bitten when trying to size graphics for these panfaces that are on site. Graphics are always too big.

All I need to know is the "viewable" area or area that is to be covered if it's a full color print. Could their be a simple mathematical standard I'm not aware of?

All I need to know is the "viewable" area or area that is to be covered if it's a full color print. Could their be a simple mathematical standard I'm not aware of?