Greetings,

I am still fairly new to vinyl cutting, and everyday I learn something new. Im using a Mutoh Kona 1400 and Oramask 813 film to make stencils. I recently noticed I am getting more "sawtooth" edges on curves where I was previously printing smooth, clean curves. How should I handle this issue?

I have read that changing the pressure of the blade or even removing the tool holder and making sure there is lubrication can fix this. I was wondering if this is common after several cuts. This machine was a "hand-me-down" from a generous vinyl shop I've worked with so it had a good long run.

Should I be replacing the blade-? Is it something more serious? Any help is appreciated!

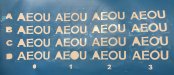

Ive uploaded an image comparing the two. The one on the left (partially obscured by transfer tape) is the clean one that I cut about a month ago. The one on the right is the new cut from today.

I am still fairly new to vinyl cutting, and everyday I learn something new. Im using a Mutoh Kona 1400 and Oramask 813 film to make stencils. I recently noticed I am getting more "sawtooth" edges on curves where I was previously printing smooth, clean curves. How should I handle this issue?

I have read that changing the pressure of the blade or even removing the tool holder and making sure there is lubrication can fix this. I was wondering if this is common after several cuts. This machine was a "hand-me-down" from a generous vinyl shop I've worked with so it had a good long run.

Should I be replacing the blade-? Is it something more serious? Any help is appreciated!

Ive uploaded an image comparing the two. The one on the left (partially obscured by transfer tape) is the clean one that I cut about a month ago. The one on the right is the new cut from today.