Silver Star DC

New Member

Hey all. Not sure if those is the right forum page or not. If it's not please let me know and I'll post somewhere else.

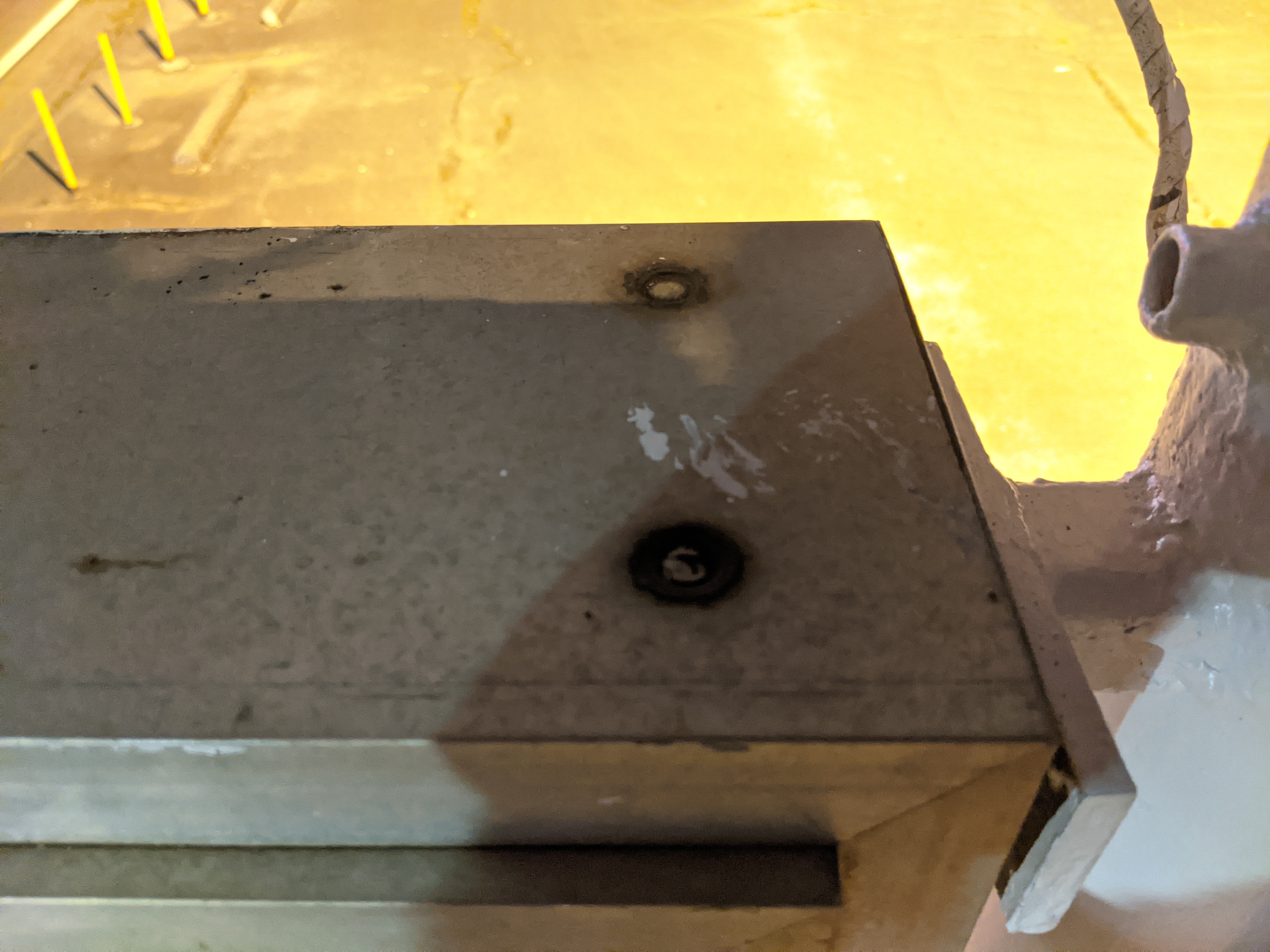

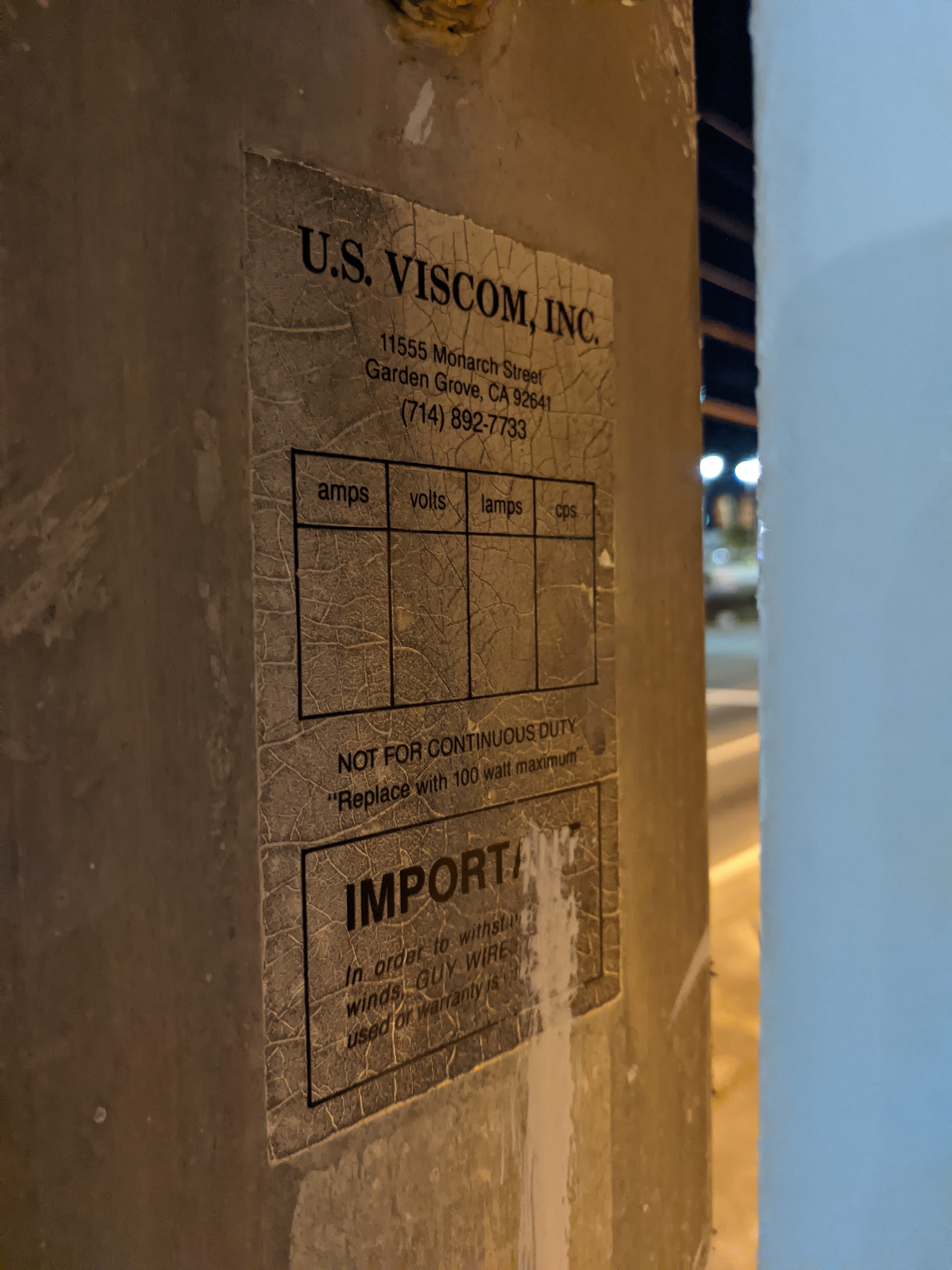

I have a sign cabinet that I am trying to change the faces in, but for the life of me I can't figure out how to take the cabinet apart. It doesn't have the typical edge to side the faces in and out. Most cabinets I've changed out have retainers butt those one doesn't. Any help would be greatly appreciated.

I have a sign cabinet that I am trying to change the faces in, but for the life of me I can't figure out how to take the cabinet apart. It doesn't have the typical edge to side the faces in and out. Most cabinets I've changed out have retainers butt those one doesn't. Any help would be greatly appreciated.

cool deal. It does look well built.

cool deal. It does look well built.