jtinker

Owner

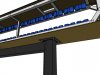

I'm in need of a sign cabinet with rounded corners. I was thinking I could just fabricate it myself out of steel and aluminium but if anyone's got any better ideas feel free on letting me know. We get some pretty nasty hurricanes down here so it would need to be sturdy enough to take up to 100mph winds atleast. Know of a company that makes them or any design plans to suggest?