Chuck Taylor

New Member

Hello, all - we are looking at doing a very large piece of sign white on an existing light box. This sign will be 48" high x 354" wide.

We were thinking of using a 51" Duraplex Impact Resistant Acrylic Roll material as we felt it would be easier to work with and transport.

Does anyone have experience using this rolled material (we have always just worked with sheets until now.

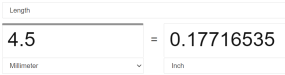

1. How difficult is this material to cut from it's standard 51" h down to 48" h (material is a 4.5ml which translates to 0.177" thick) and is this something that could be done using an Exacto knife?

2. How difficult is this roll material to install - ie: there are usually just 2 of us on each end of a ladder doing installations, is it feasible for us to assume this is something that we could install this way?

Note - we are going to apply printed / translucent CAD cut graphics to the face (not a solid coverage). Does anyone think the applied vinyl would not be okay when rolled up - ie: not lift from the acrylic when temporarily rolled up for transport?

Thank you in advance for your information and recommendations - much appreciated!

We were thinking of using a 51" Duraplex Impact Resistant Acrylic Roll material as we felt it would be easier to work with and transport.

Does anyone have experience using this rolled material (we have always just worked with sheets until now.

1. How difficult is this material to cut from it's standard 51" h down to 48" h (material is a 4.5ml which translates to 0.177" thick) and is this something that could be done using an Exacto knife?

2. How difficult is this roll material to install - ie: there are usually just 2 of us on each end of a ladder doing installations, is it feasible for us to assume this is something that we could install this way?

Note - we are going to apply printed / translucent CAD cut graphics to the face (not a solid coverage). Does anyone think the applied vinyl would not be okay when rolled up - ie: not lift from the acrylic when temporarily rolled up for transport?

Thank you in advance for your information and recommendations - much appreciated!

Attachments

Last edited: