yesterday i printed about 15 4'x6' 4mm coro sheets

we cut them a few days previous, wiped them down with large alcohol wipes a couple times and printed

all went fine

this morning i am doing a handful of 4'x8' for the same customer.

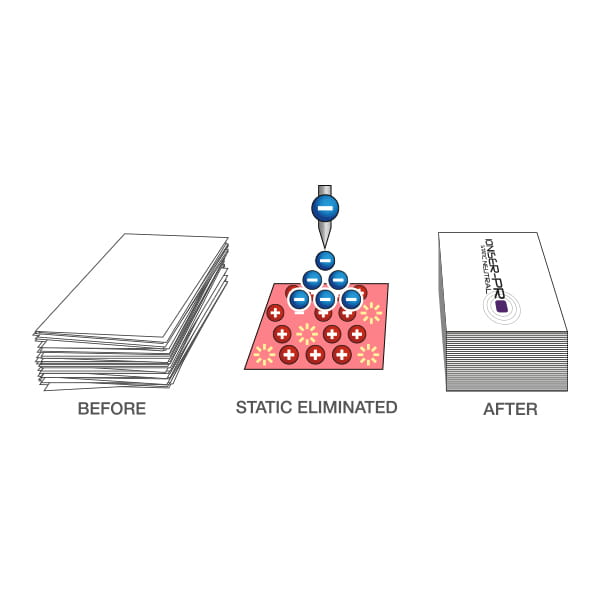

when i removed the first sheet from the cart, there was quite a bit of static electricity, the hair on my arms stood up

wiped down the same way and all is going fine, but, i know the common wisdom is that i will be better off buying a full pallet of coro, so no greasy fingerprints

doesn't this mean the full pallet will open the door to static electricity problems in the winter

(obviously i have too much time on my hands, no real problems so i have to make one)

we cut them a few days previous, wiped them down with large alcohol wipes a couple times and printed

all went fine

this morning i am doing a handful of 4'x8' for the same customer.

when i removed the first sheet from the cart, there was quite a bit of static electricity, the hair on my arms stood up

wiped down the same way and all is going fine, but, i know the common wisdom is that i will be better off buying a full pallet of coro, so no greasy fingerprints

doesn't this mean the full pallet will open the door to static electricity problems in the winter

(obviously i have too much time on my hands, no real problems so i have to make one)