Hi

we sell a lot of signs for swap meets and car shows ,

most are hung on EZ-Ups or other canopies ,

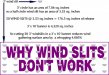

the problem is in the afternoon the wind picks up and the signs add to the "lift" to make the EZ-Ups want to fly away,

We have cut "air flaps" , a U shaped cut to let the air pressure out , but is there a better way ? Or any studies on where is the best place to put the flaps ?

Thanks for your ideas VW

we sell a lot of signs for swap meets and car shows ,

most are hung on EZ-Ups or other canopies ,

the problem is in the afternoon the wind picks up and the signs add to the "lift" to make the EZ-Ups want to fly away,

We have cut "air flaps" , a U shaped cut to let the air pressure out , but is there a better way ? Or any studies on where is the best place to put the flaps ?

Thanks for your ideas VW