Hi there,

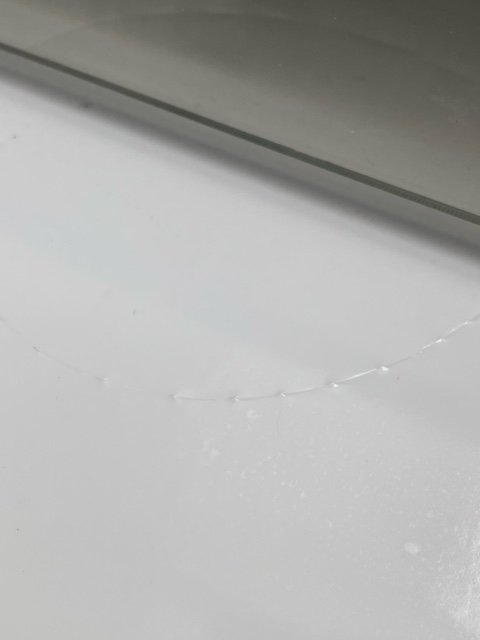

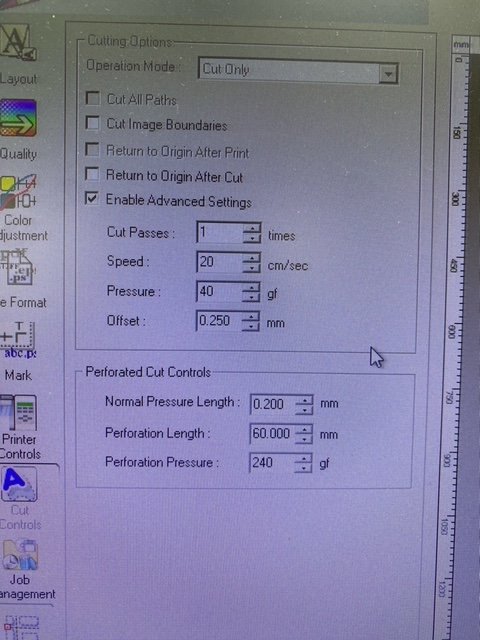

Over the last few weeks ive been unable to get a nice cut on my VS-540. Im perf cutting laminated vinyl stickers and using a new 60 degree blade. The problem is mainly happening on curved cuts like circles although squares are not perfect either. Ive never got an excellent cut on this machine but certainly not as bad as the jagged cuts im getting now.

Here is a pic of the jagged cut and another of the settings get the best result from:

Any ideas or suggestions would be most appreciated!

Over the last few weeks ive been unable to get a nice cut on my VS-540. Im perf cutting laminated vinyl stickers and using a new 60 degree blade. The problem is mainly happening on curved cuts like circles although squares are not perfect either. Ive never got an excellent cut on this machine but certainly not as bad as the jagged cuts im getting now.

Here is a pic of the jagged cut and another of the settings get the best result from:

Any ideas or suggestions would be most appreciated!