skyhigh

New Member

I know I have seen this problem addressed before on the forum, but my search turned up nothing. Perhaps I'm at a loss for the proper search words?

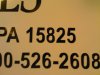

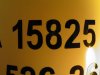

Anyways, my plotter is not making perfect cuts lately. At first it seemed that it was mostly on the smaller 1" type letters that would have an inner circle ....."O"'s, "8"'s, "6"'s....ext. But now they are actually getting distorted. The other picture shows the larger 2" letters that cut pretty well....the "O"'s seem to be the only ones with a ever so slight "nick" where the blade didn't seem to hit perfectly.

The picture with the distorted O,8 & 6 are slightly over 1/2" in height. I will mention, they weed out perfect without any hangups, but look like crap.

So where to look first? The friction wheels? This cut was 23.4" on a 24" roll, and I only used the 2 outer wheels (far left and far right), but didn't have the center one engaged.....which leads me to a possible theory, that the material has room to move around in the center, as I only have it pinched at the extreme ends of the roll???? Maybe?

To be honest, I've had this cutter for over 10 years, and have had to do "ZERO" maintaince, with the exception of a dozen or so new blades. It has been a tank. That being said, where to start to look?

Pinch wheels wear-out? ....belt?.... over extending the pinch wheels?

Thanks for looking.

Anyways, my plotter is not making perfect cuts lately. At first it seemed that it was mostly on the smaller 1" type letters that would have an inner circle ....."O"'s, "8"'s, "6"'s....ext. But now they are actually getting distorted. The other picture shows the larger 2" letters that cut pretty well....the "O"'s seem to be the only ones with a ever so slight "nick" where the blade didn't seem to hit perfectly.

The picture with the distorted O,8 & 6 are slightly over 1/2" in height. I will mention, they weed out perfect without any hangups, but look like crap.

So where to look first? The friction wheels? This cut was 23.4" on a 24" roll, and I only used the 2 outer wheels (far left and far right), but didn't have the center one engaged.....which leads me to a possible theory, that the material has room to move around in the center, as I only have it pinched at the extreme ends of the roll???? Maybe?

To be honest, I've had this cutter for over 10 years, and have had to do "ZERO" maintaince, with the exception of a dozen or so new blades. It has been a tank. That being said, where to start to look?

Pinch wheels wear-out? ....belt?.... over extending the pinch wheels?

Thanks for looking.