Annette Asberg

New Member

So it's me again with my questions.

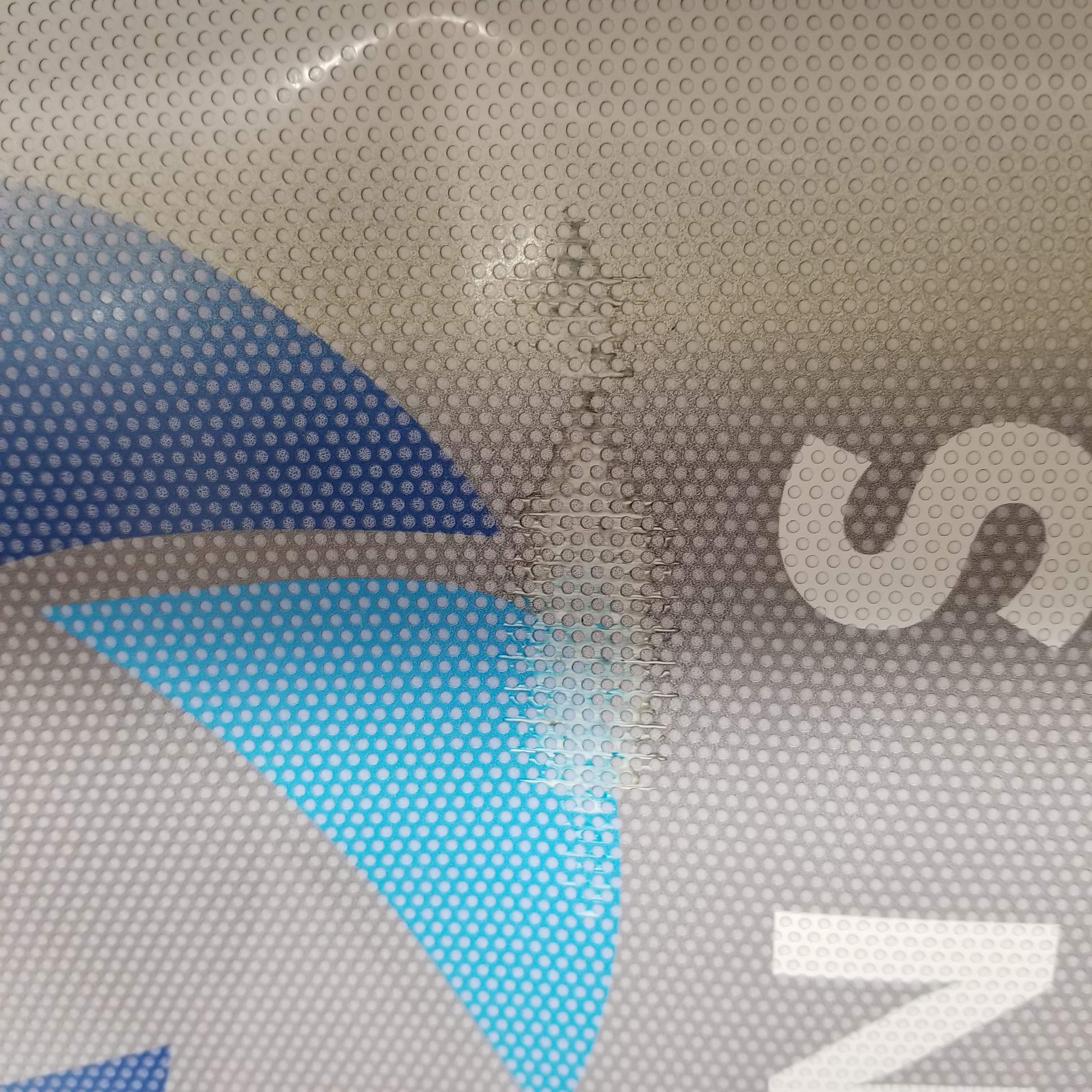

Today when I was printing on Britelines perforated 50/50 I used BL-WP 50/50 as the profile and it seemed to melt. Why would it?

Today when I was printing on Britelines perforated 50/50 I used BL-WP 50/50 as the profile and it seemed to melt. Why would it?