Hello all, this is probably a ridiculous question but figured... I started this (for me hobby) making prank auto magnets that were custom size, design an shape using a cricut machine and a cheap printer with standard sheet size printing. The problem I quickly ran into was it only had a cutting area of 12 x 12 so for most of my magnets they were 10 x 3 or 4x4 so I was very limited as to how many I could do at once. So I have expanded my "hobby" and now have a 1624 mutoh and a 54" kona 1400. The cutter doesn't cut the magnet well (I tried) and therefore I am looking for a new solution. I can't afford a $20-$30k flatbed cutter but was wondeinrg if a cnc machine would be able to do the custom shapes, designs? I am not familiar at all with the cnc but there are what seems to be a couple good used options in my area for like $3-5k. The magnetic material is 30mil so its a bit thicker than the "fridge style/strength" magnets. Is it a non starter or would it likely work out ok?

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Would A CNC Work?

- Thread starter morty87

- Start date

HulkSmash

New Member

Hand cut it. Magnetics are very easy to cut.

Odd that prank magnetics would require such large equipment. Are you receiving money for these things ??

Gino, my love. I Miss you.

I think he's trying to get custom shapes, which is why he needs a router.

James Burke

Being a grandpa is more fun than working

Steel rule dies and an old clicker press are all you need. Both are easily within the financial reach of a boot strapper.

Before moving on to where I'm at now, I had a good sideline magnet business using steel rule dies and an old Kensol K36 manual hot stamp press. The same press did both the foil hot stamping, and the die cutting (die cutting was done without heat).

I'm not affiliated with this outfit, but it shows you what can be done. They're using leather, but it will cut magnet just as easily. Skip ahead to 5:00 to see the machine in action.

JB

Before moving on to where I'm at now, I had a good sideline magnet business using steel rule dies and an old Kensol K36 manual hot stamp press. The same press did both the foil hot stamping, and the die cutting (die cutting was done without heat).

I'm not affiliated with this outfit, but it shows you what can be done. They're using leather, but it will cut magnet just as easily. Skip ahead to 5:00 to see the machine in action.

JB

Last edited:

I have never cut magnet material on a CNC, but as a CNC guy myself, I am going to say NO. Trying to cut floppy, flimsy material without vacuum hold down, forget it. And if you have vac hold down, your overhead will outpace the profitability of the magnets. Seems like that punch press thing would be a better idea.

James Burke

Being a grandpa is more fun than working

The amazing thing about cutting magnet is that you only need to score it...even the very thickest magnet sheeting or flexible magnetic strips. You must completely cut through the 3 to 4 mil vinyl, and then only about that same amount into the magnet material. Bend the material backward slightly and it will cleanly separate like magic.

We used to cut magnetic business cards on a photo mat board cutter. We'd score them both directions and then snap them apart...approx. two dozen at a time.

Obviously, magnets with extreme or delicate shapes need a deeper score, or completely cut through (tight internal radii or acute angles and such).

JB

We used to cut magnetic business cards on a photo mat board cutter. We'd score them both directions and then snap them apart...approx. two dozen at a time.

Obviously, magnets with extreme or delicate shapes need a deeper score, or completely cut through (tight internal radii or acute angles and such).

JB

Last edited:

letterman7

New Member

I used a drag knife that set in place of the router blade. Took a bit of fiddling to get the offsets where I needed them to be, but actually turned out ok. Not terribly accurate, but for the intended purposes was fine. Now, do you want to spend $10K and up on a CNC just to cut magnets, or do you want to expand your business with the CNC?

KMC

Graphic Artist

we use our CNC to cut magnet shapes all the time super easyI have never cut magnet material on a CNC, but as a CNC guy myself, I am going to say NO. Trying to cut floppy, flimsy material without vacuum hold down, forget it. And if you have vac hold down, your overhead will outpace the profitability of the magnets. Seems like that punch press thing would be a better idea.

signman315

Signmaker

CNC with a drag knife works but CNC with router bit is less viable. The drag knife can be used to score the mag and then it's easy enough to weed them out. But if cutting using a regular router it will cut fine but it will generate a lot of magnetic chips that will then stick to everything including your finished product. Might as well tar and feather the things haha.I have never cut magnet material on a CNC, but as a CNC guy myself, I am going to say NO. Trying to cut floppy, flimsy material without vacuum hold down, forget it. And if you have vac hold down, your overhead will outpace the profitability of the magnets. Seems like that punch press thing would be a better idea.

Someone mentioned you would need a camera registration system...which is ideal but also costly. But not at all necessary...you can cut light marks into the sacrificial boards on the router table and use those to line up the print sheet. I ran a Sabre 408 for 10 years and would direct print PVC/various materials on a UV printer, and just print a thin 1pt outline around the bounding box of the job....then just line up the bounding box to the edges of your marks in the CNC table and it cuts accurate all day long. I actually found it faster and just as accurate as a camera system, and once the operator gets a little skill under their belt very fast and easy. I actually cut a 48" x 96" outline into the table and used that to line up all different sheet sizes. Just had to line up the bounding box of the printed sheet to the lower left corner of the 48" x 96" marks that I cut into the table (which also happens to be the default origin point of the CNC) and could run any sheet size within 48" x 96" and cut very accurately within 1/16" or less. Accurate enough that I could cut full sheets of 6" x 6" circles, printed 2 sided, with borders in the design....the harder part was actually getting the prints to line up front to back on the UV, if that was right then cutting was cake.

GAC05

Quit buggin' me

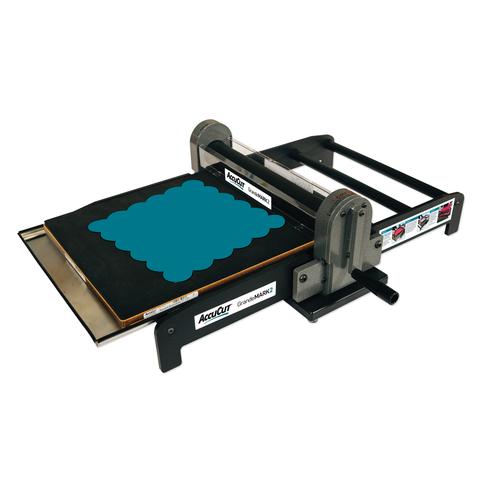

Along the lines of the clicker press, we just picked up one of these off eBay for less than $200

Depending on how big the shapes you need are it may work for you.

We are getting a custom 26"x14" die made to punch out some printed shelf talkers that can't be run on our Graphtec plotter. Quote for the die was a little over $200 for 8 nested shapes on a single board.

We tested our eBay press with the die that came with it and it cut magnet, 1mil pvc and the PET material we need for the talkers cleanly. We have monthly runs of 400 to 500 talkers that have a complex "T" shape that takes a ridiculous amount of time to cut by hand.

wayne k

guam usa

Depending on how big the shapes you need are it may work for you.

We are getting a custom 26"x14" die made to punch out some printed shelf talkers that can't be run on our Graphtec plotter. Quote for the die was a little over $200 for 8 nested shapes on a single board.

We tested our eBay press with the die that came with it and it cut magnet, 1mil pvc and the PET material we need for the talkers cleanly. We have monthly runs of 400 to 500 talkers that have a complex "T" shape that takes a ridiculous amount of time to cut by hand.

wayne k

guam usa

I started it with making prank magnets and then a close friend of mine who is the head of a baseball organization placed an order of 1k car magnets of their organization as a fund raiser. So i upgraded quick, an now don't do prank magnets as main focus, but still want to provide custom ones if i can.Hand cut it. Magnetics are very easy to cut.

Odd that prank magnetics would require such large equipment. Are you receiving money for these things ??

I started it as a hobby, but my 9-5 is with the gov and in a building with an internal buysell system. So after doing posters in my cubicle at work, word spread fast about my printing. 3k ladies with a buysell at their work so they can shop all day = winning!! So its building up with poster, canvas and decal sales but would still like to offer custom magnets. Anyways thanks for all your suggestionsYeah, unless he's doing like 10k a magnets a week. time to find a new hobby to generate money

Oh ok, thanks for the idea.Along the lines of the clicker press, we just picked up one of these off eBay for less than $200

View attachment 136330

Depending on how big the shapes you need are it may work for you.

We are getting a custom 26"x14" die made to punch out some printed shelf talkers that can't be run on our Graphtec plotter. Quote for the die was a little over $200 for 8 nested shapes on a single board.

We tested our eBay press with the die that came with it and it cut magnet, 1mil pvc and the PET material we need for the talkers cleanly. We have monthly runs of 400 to 500 talkers that have a complex "T" shape that takes a ridiculous amount of time to cut by hand.

wayne k

guam usa