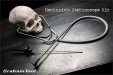

The good news: after replacing the cap-top, 9 dampers and now the head I, finally found the pressure leak. I decided to take off the cap top I replaced a few weeks ago (when things started going bad) just to make sure the lines were on the bottom nice and tight. Well there are 3 holes in the cap top...so when you hook 2 lines to them all you are doing is pulling air through that third hole. I don't have my old cap top so not sure how it's supposed to look but I know that should be sealed off (common sense and looking through various pictures online). So I put a cap over that third hole and it magically started pulling ink. Not sure if anyone has a cap top laying around that they can post pictures of what it is supposed to look like but all the spares I have also have that third hole.

The bad new is, it STILL won't do a test print. It looks like the carriage board is fried (visually) so at least I can see where the problem is. This could have something to do with the air leak as I noticed that the print head was half full of ink when I pulled the dampers out. So the ink was flowing everywhere including the circuit boards attached to the head. So on to the next part....