Stacey K

I like making signs

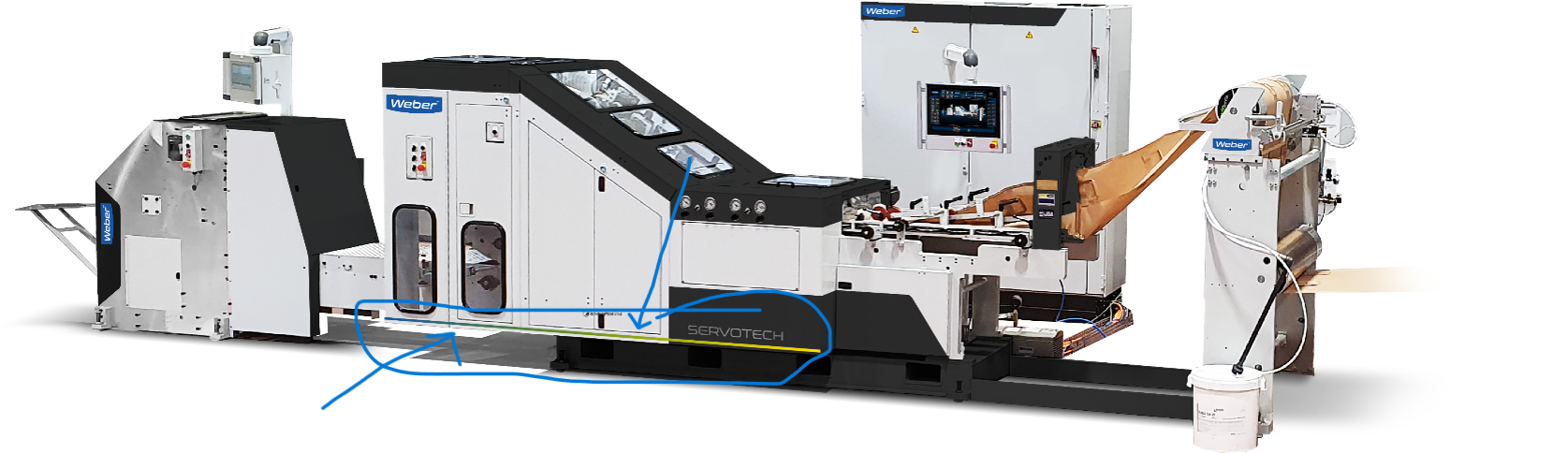

This might be the worst order yet. A decal that is 2" high x 50' long with a gradient from length to length. I have an HP315. Is there someone else that can do this on a roll instead or what might be the best way to do this. Will need to be laminated also. See below sample on a smaller machine. I have several smaller ones to do also that are 12' long. Do I dare print and laminate 12' at once?