-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Omega 5 & Windows 10?

Win10 hijacked me earlier this spring and my Omega 5 still worked...along with SignLab 9 and AutoCAD 14. I was able to roll back to Win7, thank the Good Lord... JB- James Burke

- Post #2

- Forum: Gerber Omega, Graphix Advantage & MacImprint

-

-

ADVICE

Perhaps vinyl letters adhered to a wooden sign board? JB- James Burke

- Post #18

- Forum: New Member Introductions

-

clear release liner

Oy! He's using the diamonds but he wasted 3 or 4 inches inches of vinyl in the process. Put the diamonds within the artwork bounding box and you won't waste vinyl. JB- James Burke

- Post #8

- Forum: General Signmaking Topics

-

clear release liner

The diamonds serve as registration marks, and there's no unnecessary steps or wasted material. JB- James Burke

- Post #7

- Forum: General Signmaking Topics

-

clear release liner

Do your layout utilizing all your colors. Place two diamonds (45 degree rotated square) about .5 high somewhere within your design, and as far apart as possible. Weed your vinyl and leave the diamonds attached to the backer. (You'll cut diamonds with each color) Lay your first color...- James Burke

- Post #4

- Forum: General Signmaking Topics

-

First time for this type of job... any advice?

Totally off subject, but I'm curious about their claim for helping you lose between .5 and 1.5 pounds per day. That rate is consistent only with a good case of intestinal flu. :omg: JB- James Burke

- Post #10

- Forum: Tips & Tricks

-

Using the term "die cut" vinyl lettering

Or in our line of business. Usually, diecutters run high volumes of the same job, not one-offs. JB- James Burke

- Post #26

- Forum: General Signmaking Topics

-

Using the term "die cut" vinyl lettering

Most die cut vinyl is thermal kiss-cut. It's done with a heated die plate. It's extremely fast and is ideal for extremely small letters like you see on deck lids and rear bumpers (auto dealers branding) Learn about it here...- James Burke

- Post #20

- Forum: General Signmaking Topics

-

Laser etching Mirrored Acrylic

Sandblasting will remove the silver and leave a smooth, frosted etch. Lasers do some things extremely well, unfortunately, etching is not one of them unless it's a halftone photo. JB- James Burke

- Post #2

- Forum: Laser Cutters

-

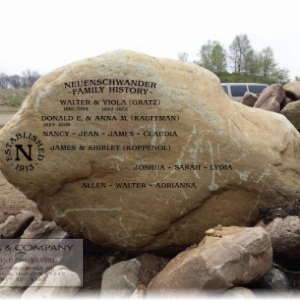

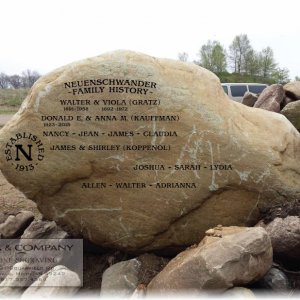

When the substrate dictates layout

About the size and shape of a VW Beetle. Always a slight bit of challenge when the shape, texture and obstacles dictate the layout (although we have the ability to shape and smooth problematic areas that inhibit the engraving). LHF Jewelo is one of my favorites for its retro appeal...- James Burke

- Thread

- Replies: 1

- Forum: Designs & Layouts

-

Member Album by James Burke

- James Burke

- Album

- Comments: 0

-

When the substrate dictates layout

- James Burke

- Media item

- Comments: 1

- Album: Member Album by James Burke

-

Just got asked for Chloroplast.

As for all that eye-sore election signage...it should all have to be 100% biodegradable...with a 90-day lifespan. JB- James Burke

- Post #4

- Forum: General Signmaking Topics

-

Contract regarding PHYSICAL Printed Proofs?

Wow...that was ironic. Whilst typing my first reply, a customer emailed me to say he specified the wrong death date for his wife's memorial. Fortunately, it's still in the pre-production process and I hadn't finished his final artwork approval papers. JB- James Burke

- Post #23

- Forum: General Signmaking Topics

-

Contract regarding PHYSICAL Printed Proofs?

Yep, this is what we do. It clearly states what we'll do if we were wrong, and it also explains what the customer should expect if they are wrong. Lately, we've had some customers saying that it looks good and to "just go ahead and run it" (they don't have time to mess around with...- James Burke

- Post #21

- Forum: General Signmaking Topics

-

Just got asked for Chloroplast.

Corrugated paperboard (cardboard) seems to come to mind... JB- James Burke

- Post #3

- Forum: General Signmaking Topics

-

Freshly painted propane tank

We just did our new job board utilizing (tough-as-nails) farm implement white enamel. I put cast vinyl on it two days after we painted it. Looking back, I probably should have waited two or three more days. While the paint was technically "dry", I believe the oil base hadn't settled down...- James Burke

- Post #6

- Forum: General Signmaking Topics

-

Jesse Hill - J Hill Designs- needs your thoughts and prayers

Such a sad ending. Thoughts and prayers for his lovely gal, and his family. JB- James Burke

- Post #76

- Forum: General Chit-Chat

-

-