Textured surface would likely be non compliant, but you can get around it by purchasing ada compliant materials for the 'panels', as printing that area is the most time consuming part anyways.

So a 7" letter only has the cost figured in, not your overhead. Not that their is a great deal of overhead with a 3d printer, but look at it this way. You can sell a 7" letter for $46.70 (just assuming you will shoot for and stop at gemini's suggested retail) So $46.70 - 4.50 for materials + 1.25 for maintenance. Let's consider a small shop rent and utilities at a combined 1,000/month, with 5/8 hour days. I'm assuming a 7" letter took about 2 hours to print, and let's just say your demand for 7" letters is banging, nothing but. So you have 1 machine, knocking out 4 a day, 20 a week, or 80 a month. At 80 a month, you'll bring in $3,736. That's great! It'll cover our theoretical rent and utilities, only 360 in materials and 100 in machine cost. But now you're left with $2,276 to pay yourself. For a month. So that'll cover a low cost employee to setup the machines. I'd think to hit a volume where you'd be bringing in enough to cover a sales guy, a part time accountant, and a hybrid 3d/graphic designer, you'll be needing about 10 printers.

Fun thing, printing onto 'glass' or other surfaces will net different finishes. The flexible pebble textured build plates are just thing gauge spring steel covered with something very close to Nekoosa Eclypse laminate, a sample roll of 10'x30" from them is free, and would net you like 20 or 30 build plates. (You'll want extra build plates if you venture into petg or PC, as those can straight up weld themselves to the build plate if your initial layer height is not ideal.)

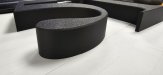

What printer are you running? Your letters look sharp, keep it up!