-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

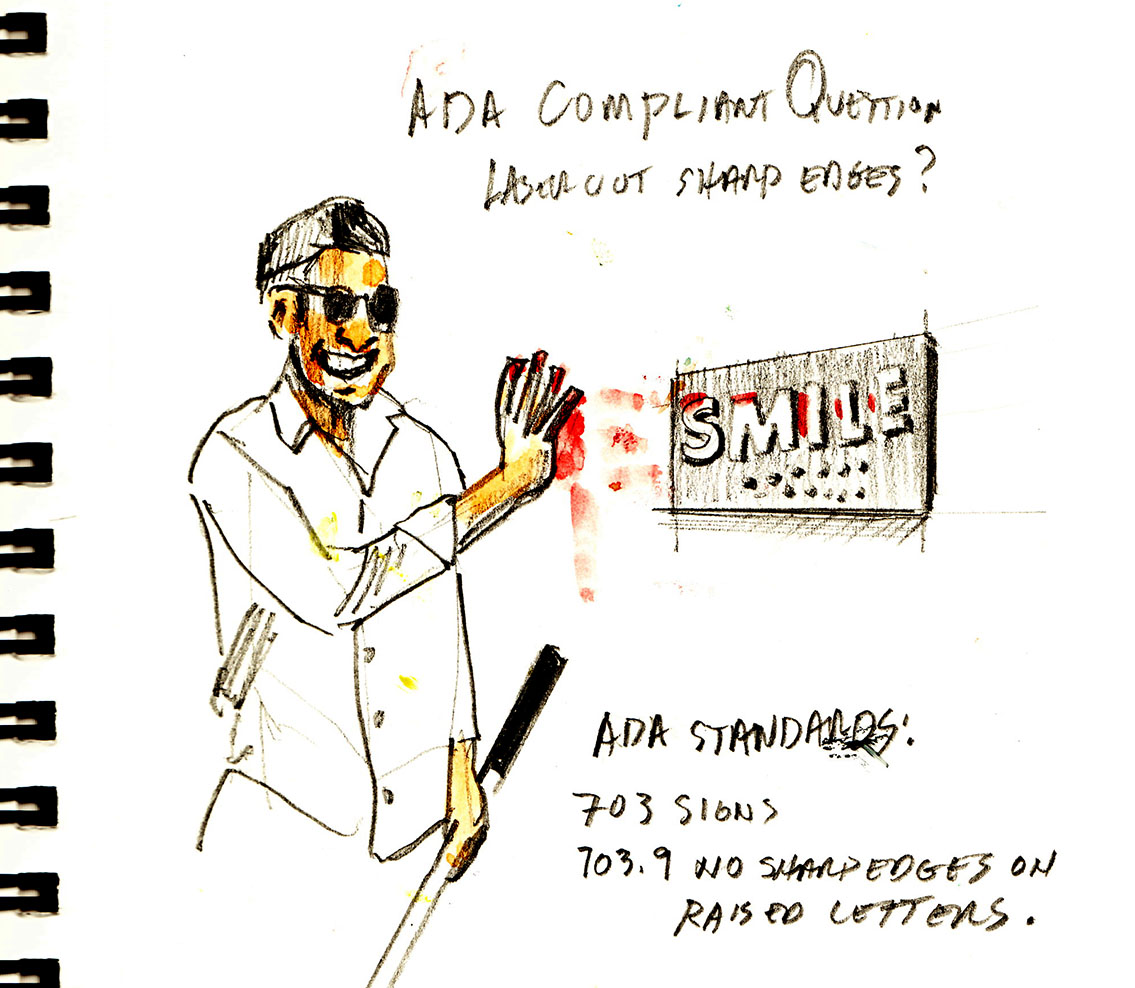

Ada Compliant Question

- Thread starter PreImp

- Start date

one of the other points is the height that the tactile is raised above the surface, a minimum of 1/32"

I thought the same,but then I saw this Advisory 703.2. I don't know if the laser edge would be considered sharp or abrasive. It would be a square edge.. What do you think?

I pulled this from the

2010 ADA Standards for Accessible Design

see Advisory 703.2,

703 Signs

703.1 General. Signs shall comply with 703. Where both visual and tactile characters are required, either one sign with both visual and tactile characters, or two separate signs, one with visual, and one with tactile characters, shall be provided.

703.2 Raised Characters. Raised characters shall comply with 703.2 and shall be duplicated in braille complying with 703.3. Raised characters shall be installed in accordance with 703.4.

Advisory 703.2 Raised Characters. Signs that are designed to be read by touch should not have sharp or abrasive edges.

703.2.1 Depth. Raised characters shall be 1/32 inch (0.8 mm) minimum above their background.

703.2.2 Case. Characters shall be uppercase.

703.2.3 Style. Characters shall be sans serif. Characters shall not be italic, oblique, script, highly decorative, or of other unusual forms.

703.2.4 Character Proportions. Characters shall be selected from fonts where the width of the uppercase letter "O" is 55 percent minimum and 110 percent maximum of the height of the uppercase letter "I".

703.2.5 Character Height. Character height measured vertically from the baseline of the character shall be 5/8 inch (16 mm) minimum and 2 inches (51 mm) maximum based on the height of the uppercase letter "I".

EXCEPTION: Where separate raised and visual characters with the same information are provided, raised character height shall be permitted to be 1/2 inch (13 mm) minimum.

Rick

Certified Enneadecagon Designer

It's my understanding that if they required an eased/domed edge that engraving allows, that it would be preferring one method of fabrication over another. My beef with that advisory is what constitutes sharp... if the letter can draw blood? Obviously that would not be good on any sign. I think that advisory is purposely vague and it's up to the fabricator and inspector to determine what is too sharp... are you going to slightly ease every letter by hand? Your competition is going to cut and stick as they are because their version of sharp is different the yours.

By the way, how are you making your braille?

By the way, how are you making your braille?

Yes it is pretty vague. I agree with that.. As of right now I sub out both the tactile and braille. I've been toying with the idea of bringing it inhouse and using the my laser engraver to do the tactile, but the braille would be another story I have a multicam router, but I think it would be pretty difficult to dial in the proper hole depths for the braille. Any thoughts on that??

Rick

Certified Enneadecagon Designer

Yes it is pretty vague. I agree with that.. As of right now I sub out both the tactile and braille. I've been toying with the idea of bringing it inhouse and using the my laser engraver to do the tactile, but the braille would be another story I have a multicam router, but I think it would be pretty difficult to dial in the proper hole depths for the braille. Any thoughts on that??

I worked at a shop that used a 2 x 2 Multicam where they made a custom mount for an engraving head. I would even out the spoil board with the router head, then with the engraving head make marks for sign placement on the board and then carefully taped 8-10 signs at a time... find my '0' point, first doing the tactile, then the braille. It worked pretty good at the time... this was around 1997

I think a large bed engraver would be preferable after seeing one in action.

GaSouthpaw

Profane and profane accessories.

As Rick says, it is entirely possible to do the Braille on a router. Make sure you:I worked at a shop that used a 2 x 2 Multicam where they made a custom mount for an engraving head. I would even out the spoil board with the router head, then with the engraving head make marks for sign placement on the board and then carefully taped 8-10 signs at a time... find my '0' point, first doing the tactile, then the braille. It worked pretty good at the time... this was around 1997

I think a large bed engraver would be preferable after seeing one in action.

- Definitely have a level, smooth surface for drilling the correct depth.

- A good vacuum table helps, too.

- Braille bits.

If you want to produce them properly (legally), you also have to have a Braille license. Accent Signs holds the patent on raster Braille (which is the standard method) and you can purchase the license and Braille pen (which you're going to want one, trust me) from them directly.

Since you're in California, your standards will be different from everyone else's (see here)- so make sure you follow the state regulations. If you're doing them for outside the state, the "normal" requirements apply (the ones you've quoted above).

If you run EnRoute, a Braille translator is available as an upgrade. EngraveLab is another option I'm actually familiar with that has the option. The same likely applies for other programs. Otherwise, Duxbury is the standard translator, if I recall. Keep in mind Braille is rarely ever a letter for letter translation.

If you buy an engraver, make sure the program that comes with it has the translator.

As to your other question- plenty of people make ADA signs with laser cut tactile, and it's never questioned. I'm not sure how well that would fly in California, though.

Good luck!

Zendavor Signs

Mmmmm....signs

Though it is preferable for the tactile to have eased edges... nowhere in the ADA code is it required.

It's the braille that is required to be "domed"

When we purchased our Vision engraver a couple years ago, the trainer said tactile lettering cut on a rotary machine (eased edges) required 1/16" spacing between the lettering, whereas laser cut tactile lettering requires 1/8" spacing. Is that in the ADA code anywhere?

When we purchased our Vision engraver a couple years ago, the trainer said tactile lettering cut on a rotary machine (eased edges) required 1/16" spacing between the lettering, whereas laser cut tactile lettering requires 1/8" spacing. Is that in the ADA code anywhere?

This is what I found.. Thank you to everyone for all of the informative posts.

703.2.7 Character Spacing. Character spacing shall be measured between the two closest points of adjacent raised characters within a message, excluding word spaces. Where characters have rectangular cross sections, spacing between individual raised characters shall be 1/8 inch (3.2 mm) minimum and 4 times the raised character stroke width maximum. Where characters have other cross sections, spacing between individual raised characters shall be 1/16 inch (1.6 mm) minimum and 4 times the raised character stroke width maximum at the base of the cross sections, and 1/8 inch (3.2 mm) minimum and 4 times the raised character stroke width maximum at the top of the cross sections. Characters shall be separated from raised borders and decorative elements 3/8 inch (9.5 mm) minimum.

Yes, you can use a laser to produce the raised elements of ADA signs. Generally speaking, a lot of ADA signs are not compliant for one reason or another. Most often it's down to the spacing between characters. Typically, they are too close together. Otherwise often the contrast ratios are off or the materials are wrong.

In the end, it all boils down to the inspector. As we all know, inspectors control whether you pass or fail. On a big project, it's wise to make a sample and show it to the inspector and make sure they don't have any complaints.

What I've always found completely ironic about ADA signs is I do a fair bit of signs for the local municipalities. Not once have I made them an ADA sign. It's amazing how they don't need to follow their own rules.

In the end, it all boils down to the inspector. As we all know, inspectors control whether you pass or fail. On a big project, it's wise to make a sample and show it to the inspector and make sure they don't have any complaints.

What I've always found completely ironic about ADA signs is I do a fair bit of signs for the local municipalities. Not once have I made them an ADA sign. It's amazing how they don't need to follow their own rules.

Rick

Certified Enneadecagon Designer

It may not actually boil down to the inspector but the lawsuits that come about by lawsuit hungry lawyers and their clients looking to settle for a quick buck.

In California, it's a $10,000 fine for each violation... that fine is levied on the building owner, then the building owner sues the sign shop who supplied the bogus signs. Also, in California, most municipalities and projects funded by the state have to be approved by the State Architect. Over here, they are usually compliant. It's not hard to make a compliant sign, it's hard for the building owner, interior designer or the architect to approve them or when you are going up against a shop who are not making compliant signs, their bid is going to be lower.

In California, it's a $10,000 fine for each violation... that fine is levied on the building owner, then the building owner sues the sign shop who supplied the bogus signs. Also, in California, most municipalities and projects funded by the state have to be approved by the State Architect. Over here, they are usually compliant. It's not hard to make a compliant sign, it's hard for the building owner, interior designer or the architect to approve them or when you are going up against a shop who are not making compliant signs, their bid is going to be lower.

Johnny Best

Active Member

Here's a lawsuit.

signbrad

New Member

Advisory 703.2 Raised Characters. Signs that are designed to be read by touch should not have sharp or abrasive edges.

Note that the advisory does not specifically say that "characters" should not have sharp or abrasive edges. It says "signs" should not have them. Obviously, the characters should not be capable of cutting skin, but I've never seen any that were.

The company I work for does hundreds of ADA signs every year and has been making them for many years. We produce them with a number of different methods, including routing, engraving, sandblasting and photopolymer. There has never been a problem, regardless of the production method, with character edges sharp enough to cause injury.

On the other hand, it is a different matter with the edges of the sign blank itself. It is possible for a saw-cut edge on a piece of acrylic to be sharp enough to cut a finger, especially if the corners are square. It can be even worse if the blank is face-laminated with Chemetal or some other thin metal layer. Even worse yet if the metal face-laminate overhangs the substrate a bit. Formica can cut, too, as I know only too well from my two-year stint at a countertop shop in the late 1960s.

It should also be noted that reading Braille does not involve finger movements that are overly brisk or that involve firm pressure. My blind uncle moved his fingertips along in a gentle, steady pressing action along a line of Braille as if he were pressing on each of the Braille cells as he moved sideways. He actually used both hands, using his left as kind of a guide to keep his right hand fingers (the two first fingers actually) squarely on top of the line of Braille. Of course, maybe that was just his way. And he may have been a slow reader. Also, I watched this as a teenager, so it was a long time ago. My memory may be faulty.

At any rate, I suspect that Advisory 703.2 reflects concern over sign edges and corners more so than the edges of raised characters.

Brad in Kansas City

Johnny Best

Active Member

In all the years since ADA has been law, have never seen anyone read Braille in an elevator, bathroom, stairway sign or office numbers depicting where something is located.

I would be very curious to watch someone with that talent "read" braille.

I would be very curious to watch someone with that talent "read" braille.