White Haus

Not a Newbie

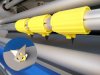

Has anyone added slitters to their roll laminators? I know some come with them, including our ancient GBC Titan, but for the life of me I can't figure out how we could actually make use of them the way they're mounted.

I figured I could just rig up some kind of OLFA blade on each side that's retractable but curious if anyone else has come up with something.

The main goal would be to have something adjustable & retractable that can be used to cut down the edge of laminate/vinyl that inevitably accumulates on long runs.

I figured I could just rig up some kind of OLFA blade on each side that's retractable but curious if anyone else has come up with something.

The main goal would be to have something adjustable & retractable that can be used to cut down the edge of laminate/vinyl that inevitably accumulates on long runs.