rudeez

New Member

Hi!

Been doing quite many signs and car jobs by now, still im quite new to the bussiness.

Doing Aluminium signs today. Always applying vinyl graphics using water with a drop of soap. Sometimes i get no "waterbubbels" at all and sometimes it's just alot of them everywhere. You know when you squeege and they just wont go away, just floats around under the decor.. Today im having those problems on the alu signs, used the same material for car graphics some days ago and was spot on. Im just wondering what tips you have for this?

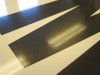

On the attached image i've squeeged for like 5 mins on the same letter "M" and still it looks quite bad, but as i said, it's watermix.

Im also wondering if this water that is still under there will go away by itself by drying a few days or if it dryes in sunlight etc?

This vinyl is the image perfect 5700 series, using R-Tape conform (paper) for application tape. Don't think it's my technique really, squeeging from middle to outsides alot and hard for atleast 5 mins ontop of the r-tape before removing it...

Please help me.

Been doing quite many signs and car jobs by now, still im quite new to the bussiness.

Doing Aluminium signs today. Always applying vinyl graphics using water with a drop of soap. Sometimes i get no "waterbubbels" at all and sometimes it's just alot of them everywhere. You know when you squeege and they just wont go away, just floats around under the decor.. Today im having those problems on the alu signs, used the same material for car graphics some days ago and was spot on. Im just wondering what tips you have for this?

On the attached image i've squeeged for like 5 mins on the same letter "M" and still it looks quite bad, but as i said, it's watermix.

Im also wondering if this water that is still under there will go away by itself by drying a few days or if it dryes in sunlight etc?

This vinyl is the image perfect 5700 series, using R-Tape conform (paper) for application tape. Don't think it's my technique really, squeeging from middle to outsides alot and hard for atleast 5 mins ontop of the r-tape before removing it...

Please help me.