S

scarface

Guest

Hey guys, in another post i mentioned the job coming up tomorrow for a customer who wants the old sign taken down and new one up.

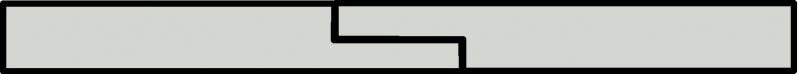

Here is the sign box i'm talking about, I'm thinking now i may try to install the face myself with a friend or two but how does a back lit face come out?

Also, the total size is 18ftx2.5ft, any idea why the other company made a split between the T and A?

Also does anyone know what permits i would need for my company to do this, which is just me and a friend?

I really wanna nail this job, new business would need window graphics, banners, cards, menus etc

Thanks!

Here is the sign box i'm talking about, I'm thinking now i may try to install the face myself with a friend or two but how does a back lit face come out?

Also, the total size is 18ftx2.5ft, any idea why the other company made a split between the T and A?

Also does anyone know what permits i would need for my company to do this, which is just me and a friend?

I really wanna nail this job, new business would need window graphics, banners, cards, menus etc

Thanks!

Attachments

Last edited by a moderator: