GP

New Member

After 3 years, I have yet to get consistant results with our profile setting for Ultraflex/Jetflex banner on our L25500 at 10 pass.

I may have tweaked the out of the box settings at one point, but media settings are as follows:

Curing: 100 C

Drying: 55 C

Vacuum: 5

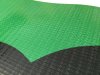

As you can see i the attached, the coverage is pretty shotty. I am not sure if this is a temperature thing, a bad media thing, or what.

Then, in the out of focus second picture, you can see the black coverage is perfect.

Any hints on how to get this thing working correctly?

I may have tweaked the out of the box settings at one point, but media settings are as follows:

Curing: 100 C

Drying: 55 C

Vacuum: 5

As you can see i the attached, the coverage is pretty shotty. I am not sure if this is a temperature thing, a bad media thing, or what.

Then, in the out of focus second picture, you can see the black coverage is perfect.

Any hints on how to get this thing working correctly?