Susan Stewart

New Member

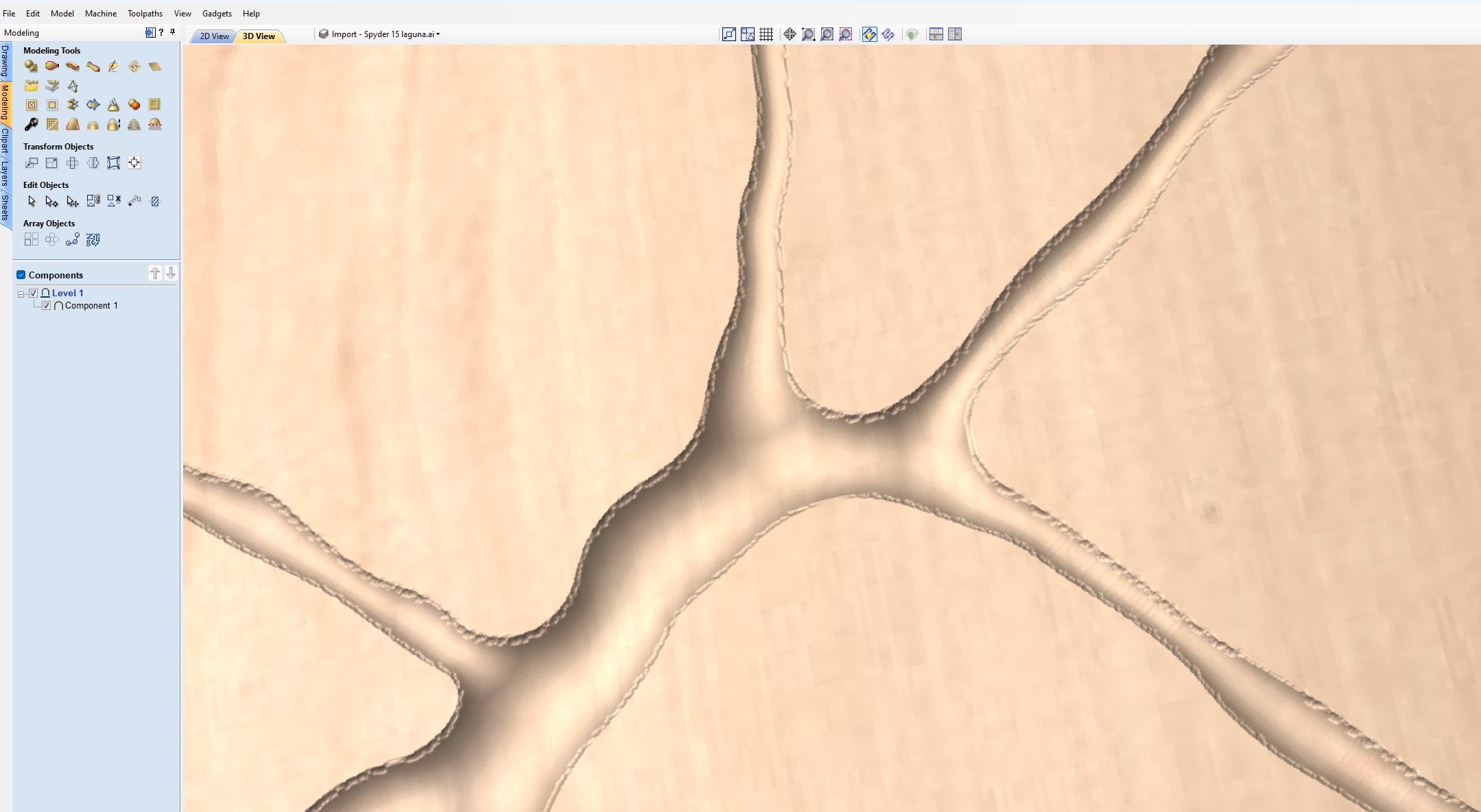

Good morning all. We went ahead and upgraded from VCarve Pro to Aspire software so we can do 3D modeling on our CNC router. We have a program that we drew, but it has some chatter. Does anyone know what we should do to get rid of this chatter? We are cutting a concave pattern on 1/2" MDF.