Hi , i have an issue , i am unable to have a clean cut.

I tried the following ways but im still unable to get a clean cut (perf cutting).

1 - Put the blade in tool position number 1 but the result was that it was eating the cutting strip to fast.

2 - Try with different blades (clean cut blades, 30 degrees , 45 degrees with the blade holder red and and blue tip)

3 - Tried all the line cut types (dotted , straight lines and others)

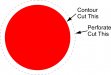

Here are somes pictures so you can see.

Thanks

I tried the following ways but im still unable to get a clean cut (perf cutting).

1 - Put the blade in tool position number 1 but the result was that it was eating the cutting strip to fast.

2 - Try with different blades (clean cut blades, 30 degrees , 45 degrees with the blade holder red and and blue tip)

3 - Tried all the line cut types (dotted , straight lines and others)

Here are somes pictures so you can see.

Thanks

Attachments

Last edited: