-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clean edges on cnc routed dibond

- Thread starter jhd

- Start date

Ken M. Klein

New Member

Go to the local hardware store and buy a de-burring tool to finish the edges by hand after routing. We've been doing that for years and it works like a charm.

Brian Guthrie

New Member

I know this sounds crazy, on square pieces I coin the edges over by rolling across vinyl holding steel roller set. Makes a beautiful edge that just forms the burr over so that no sharp edges remain. Ok shaped pieces quick sand to knock the burr off is fast.

Superior_Adam

New Member

We cut 3mm and 6mm ACM a lot with our Zund and the edges come out clean as can be, no need to do any sort of work after. I would check with Gerber and see what they recommend for that material as far as bits and speed settings.

A router is a router.....sure would like to know what bit, feed and speed you are using if it is coming out perfect every timeWe cut 3mm and 6mm ACM a lot with our Zund and the edges come out clean as can be, no need to do any sort of work after. I would check with Gerber and see what they recommend for that material as far as bits and speed settings.

Superior_Adam

New Member

Different routers will have different settings. Not all routers are created the same. We are at a router speed of 46,600 moving at 8 in/sec using a Zund 154 bit. I will caution you that there is a very good possibility those setting wont work for your Gerber. A lot of the setting are based on the actual router capabilities itself. Zund came out with a 3.6 kW router about a year after we bought ours and I know it will route faster than the one we have.A router is a router.....sure would like to know what bit, feed and speed you are using if it is coming out perfect every time

Using a gerber gold .125 bit... Now i just switched to a gerber platinum bit that is rated for dibondMy last run was at 19k rpm... feed rate of 25 plunge at 10

RyanT

Director of Entropy

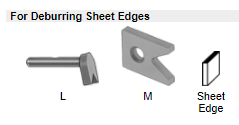

Besides trying sharp bits with different flute counts and rpms, hand held deburring tool with swappable bits:

(McMaster-Carr)

mcmaster-carr pn 4289A11

Depending on the thickness, these bits (L) will debur both sides at once (mcmaster-carr pn 4289A86)

This is from metal machining background, not really a sign specific tool.

(McMaster-Carr)

mcmaster-carr pn 4289A11

Depending on the thickness, these bits (L) will debur both sides at once (mcmaster-carr pn 4289A86)

This is from metal machining background, not really a sign specific tool.

Attachments

I've been cutting ACM for 8 years. The right router bit makes all the difference. My favorite bit is a Belin 33635. It is a solid carbide 1/4 inch single flute up cut spiral O. I cut at 14,000 rpm at 120 ipm. The bit leaves very little edge to worry about. Put the good face down so cutting letters would be a mirror cut. If it ever leaves a sharp edge it's on the back side and a quick pass with a deburring tool takes care of it. Onsrud also makes a high quality single O flute bit but I feel the Belin cuts just a hair cleaner. The Belin bit has a tighter ripple pattern on the backside of the bit, but I'd be happy with the results of either one.

I don't think a deburring tool will help him if his cuts are coming out like a tuna can. He needs the right router bit with the right feed and speed.Besides trying sharp bits with different flute counts and rpms, hand held deburring tool with swappable bits:

(McMaster-Carr)

mcmaster-carr pn 4289A11

View attachment 133807

Depending on the thickness, these bits (L) will debur both sides at once (mcmaster-carr pn 4289A86)

View attachment 133805

This is from metal machining background, not really a sign specific tool.

If that's 25 inches per minute you are running way too high rpm and way too slow feed rate. That heats up and dulls the bit real fast.My last run was at 19k rpm... feed rate of 25 plunge at 10

Patentagosse

New Member

AluPanel is .030 and their lighter version, AluPaneLite is .20... Sure the thicker the better to avoid waving on the edges...

Bly

New Member

We always get a bit of a burr after cutting on our Zund.

A quick go over with a cordless sander soon fixes them up.

We tested a few brands to see which routed cleanest and one .3 skin did cut cleanly but as we use a lot of this stuff for a price sensitive customer decided to go for a cheaper product.

A quick go over with a cordless sander soon fixes them up.

We tested a few brands to see which routed cleanest and one .3 skin did cut cleanly but as we use a lot of this stuff for a price sensitive customer decided to go for a cheaper product.

Here we use a 1/8" straight bit from Centurion Tools

We run at 150ipm and 15,000 rpm. One pass, climb cut. Using climb cut, the chips of material stay in the kerf, alleviating the need for tabs, and also stick to the waste side of the cut (mostly) I'm sure others have better methods, but it works for us. YMMV.

We run at 150ipm and 15,000 rpm. One pass, climb cut. Using climb cut, the chips of material stay in the kerf, alleviating the need for tabs, and also stick to the waste side of the cut (mostly) I'm sure others have better methods, but it works for us. YMMV.