HayTay

New Member

Any body got the plans to build a home built?

any body got plans they wish to share?

JGRO Router Table - PDF Format

JGRO Router Table - DXF Format

JGRO Router Table - SolidWorks Format

JGRO's PLOG

Joes CNC Model 2006 R-1 (E-dwg 02-06-06)

Joes CNC Model 2006 R-1 PLOG

Joes CNC Model 2006 PLOG

and the ultimate resource for CNC info... CNCzone

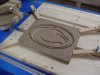

I've built the JGRO Router Table with my own two hands and minimal power tools (table saw, drill press, hand drill, and a router). Joe's design, on the other hand, pretty much requires being cut on a CNC table (JGRO's table can do it with a little fudging). By the time you get the material, nuts, bolts, screws, aluminum angle, bearings, motors, cable, primer, paint, power supply, motor controller, CNC controller software, router, end mills, router bits, a solid table, etc., etc., etc. it doesn't turn out as inexpensive as you think. But, man is it fun to cut stuff out! There is a definite learning curve depending on your current skill set. Most people here on Signs101 have the design part down. Getting it to cut is a different story.

CNC routing, it's another whole world. Check out the above plans and PLOGS for a start.

IHTH,