-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Contour cuts WAY OFF !!!

- Thread starter autoexebat

- Start date

autoexebat

New Member

Hey I have a correction , the cuts I made earlier was on 8 mil material . Not 12 .

I'm printing now , Will report back

I'm printing now , Will report back

autoexebat

New Member

Ok ran the test and it came out the way it should ... I don't know why it came out good but whatever ... Thats the funny thing , because sometimes it's good and other times it's way off .

This time I set the speed to 5 instead of 2 . Other than that nothing else was changed.

This time I set the speed to 5 instead of 2 . Other than that nothing else was changed.

autoexebat

New Member

It looks like I may have figured it out , The blade I have requires a 1mm offset. It could still improve but by far I can at least work with it.

I really don't think I should have figured this out on my own , that is the only part that upsets me. I left 2 messages for the company I got it from to give me a little help .. Never got a call back.

Kinda feel as if I got a little bent over on this deal , but as long as I can figure it out on my own , or help from you guys I am happy.

I really don't think I should have figured this out on my own , that is the only part that upsets me. I left 2 messages for the company I got it from to give me a little help .. Never got a call back.

Kinda feel as if I got a little bent over on this deal , but as long as I can figure it out on my own , or help from you guys I am happy.

toomeycustoms

New Member

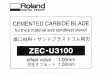

What kind/brand of blade requires a 1mm offset? We usually only require a .25 or .5 offset. http://support.rolanddga.com/docs/D...vices/Downloads/RA_Cutter Blade Knowledge.pdf

Also, what dealer doesn't answer their phones?

Also, what dealer doesn't answer their phones?

autoexebat

New Member

autoexebat

New Member

oops , nevermind ! I thought I had it fixed but after looking at my print just now in the printer I see they are off again . I guess the fight still goes on

toomeycustoms

New Member

It sounds to me like it is something when you are laminating and/or reloading the media and registering the crop marks. What happens if you just print and immediately cut the design without laminating or unloading the machine? Does it cut accurately?

Sign Works

New Member

It sounds to me like it is something when you are laminating and/or reloading the media and registering the crop marks. What happens if you just print and immediately cut the design without laminating or unloading the machine? Does it cut accurately?

I think I would try a straight print/cut without reloading then try a print/cut w/crop marks, reloading the media to cut but not laminate. Results of these two tests may help determine if it's an optical alignment issue or not. If both tests are successful then it's possibly an issue with the optical sensor reading the crop marks through the thick lam.

Tim Kingston

New Member

Do you have any plotter pens? We use them any time we think we may have issues especially with expensive materials. Just run your normal sequence with the pen installed instead of the blade holder. If all is well , the ink wipes right off the laminated surface with a little alcohol before cutting. I assume you are using " auto align" when setting up? I thought the "get media width" was your problem too. Your EPS margin is set .10in or so ?

LittleSnakey

New Member

Do your cuts start on then gradually get farther off?

Our vp-540 would do that when ushing higer blade pressures.

It may work better for you using less pressure and sending the cut twice.

Our vp-540 would do that when ushing higer blade pressures.

It may work better for you using less pressure and sending the cut twice.

I wish I had words to say today , but I am SOOOOOOOOO upset ... I took a break for a few days and just left things alone , Now I have the Roland going behind me as I type and I can see yet again my contour cuts are off . I setup all cuts in Corel to go inside of graphics. I exported that to an eps and loaded it to Versaworks .

I didnt change a thing after laminating it , I simply loaded it back in and selected CUT and set force / speed .

I have all pinch roolers setup in the Roland as well , I am beyond MAD at this point ... I have easily waster $500.00 in material and more than that in sales I have refunded due to being late ..

WOW ............wow wow

I included pictures of the 50th failure and I included a picture of how it's setup in Corel . As you can see the contour line is set correctly.

Sorry you are still struggling 50 attempts is a bit silly

they

are a long way out so.

is the first cut in the right place then miss cuts.

As said you must prove the system with the pen stop wasting materials.

As I said in post no 6 don't use centre on media

I have a vs and the cut is spot on laminated or not.

Any roll plotter will struggle with consistent accurate cutting of mx quality materials i have got the t shirt.

I also have a flat bed cutter just for the mx stuff and love It. . Just does it every time no hassle then cuts the backing for the quality finish.

Part of the roll plotting problems with mx materials are inconsistent temp and the media buckles causing it to miss track. Very sharp corners will cause the same

they

are a long way out so.

is the first cut in the right place then miss cuts.

As said you must prove the system with the pen stop wasting materials.

As I said in post no 6 don't use centre on media

I have a vs and the cut is spot on laminated or not.

Any roll plotter will struggle with consistent accurate cutting of mx quality materials i have got the t shirt.

I also have a flat bed cutter just for the mx stuff and love It. . Just does it every time no hassle then cuts the backing for the quality finish.

Part of the roll plotting problems with mx materials are inconsistent temp and the media buckles causing it to miss track. Very sharp corners will cause the same

autoexebat

New Member

Threw a ton of material in the garbage again today , From what I gather so fat this COULD be the issue.

Once you setup a file and print it , you have to laminate it and print it the same day ...

Seems once the machine is off then back on a day later is changes something ... I dont know why

I printed a set over the weekend and today cut them and it was all off completely .. NOTHING was changed in versaworks other than the cut depth

Once you setup a file and print it , you have to laminate it and print it the same day ...

Seems once the machine is off then back on a day later is changes something ... I dont know why

I printed a set over the weekend and today cut them and it was all off completely .. NOTHING was changed in versaworks other than the cut depth

rjssigns

Active Member

Maybe the Cut Carriage cable is bad. Just because a machine is brand new doesn't mean everything is perfect. Next morning after we had our printer installed it barfed ink from both ends all over the floor. That was a sight to behold.

Anywhoo.....

We started having all kinds of issues with our Roland SP540 messing up cuts. Replaced the Cut Carriage cable and that was an amazing improvement.

Still has issues with anything over 4 or 5 feet though.

Need to figure out where the rest of the error is coming from. We used to do dragster and truck graphics that were over 11 feet without issue.

Anywhoo.....

We started having all kinds of issues with our Roland SP540 messing up cuts. Replaced the Cut Carriage cable and that was an amazing improvement.

Still has issues with anything over 4 or 5 feet though.

Need to figure out where the rest of the error is coming from. We used to do dragster and truck graphics that were over 11 feet without issue.

autoexebat

New Member

After I read your post I sat here and thought about the kits I have issues with ... and POOP a thought came into my mind

Anything over 5 feet for me goes in the trash , anythnig less is fine.

Anything over 5 feet for me goes in the trash , anythnig less is fine.

autoexebat

New Member

OK so after all of this testing and tons of money down the drain I ( think ) I managed to fix my own problem . It was the way the media was loaded into the machine , its it's not alligned in the machine 100% dead on and straight its good , but if it goes off track at all then forget it ..

Cutting a kit right now so will report back.

Cutting a kit right now so will report back.

autoexebat

New Member

Sorry forgot to report back . It failed again so that wasnt the problem.

Sign Works

New Member

This is really basic but are you leaving enough material (approx 3"-4") before and after crop marks to keep sensors covered?

LittleSnakey

New Member

have you tried sending the cut twice with less pressure?

read this quote because this is what happens I know through experience.

read this quote because this is what happens I know through experience.

Someone that has experience cutting thick material is more than welcome to correct me... because I haven't before... but is it possible that the combination of his slow cutting speed (2), and the high cutting pressue (150) is manipulating the material? Basically causing it to "slip" between the rollers?

SP