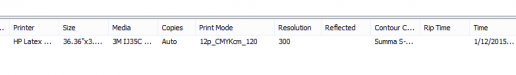

yes heaters are on I downloaded the IJ35c profile from the front panel. I printed it first in 10pass and it looked pretty bad. So I added a 12pass mode (was not on the original file) did the density test print everything looked good and I picked the 120% option. But every time I print something that is round or curved it looks bad. My Installer was not much help all we printed during his time was the calibration print and some of the ink density prints from the front panel and a ICC profile chart. We had issues with the grimco gloss house vinyl I had as it was puckering due to the heat. Right now I feel like I have a big paperweight, my 10 year old Roland puts this printer to shame I hope I can get this figured out.

So it looks like a poor profile or incompatible media.

A good approach on SAV is to select 10pass 100'c and then run the test file - check the ink levels looking carefully at the edges of the bleed patches and see which ink level seems best.

If the best one isn't the max ink - then increase the temp by 5-10'c and reprint - it may be that you can now choose a higher ink limit.

If the heat is causing issues lower it in the knowledge your ink limit will be lower.

Then enter the final ink limit and move on the the next stage, the calibration then icc

When you have saved the profile you can try a faster one starting at 8pass but following the same profiling logic - some SAV is fine at 8pass but some need 10 or 12.

With a 360 there's little point tweaking a canned profile - even the downloaded ones are not great.

Do your own from scratch and keep a close eye on the bleed patches and you should see an improvement.