Hello everyone. I am back looking for some expert advice. This one is a little different though.

I'm sure everyone here has seen or at least heard about other industries jumping into the fight against Covid-19. Here at our little shop, we are hoping to jump in and help out if we can. I have come across some articles and videos online about producing your own protective face shields. We want to produce and distribute some of these at no charge for our local hospital and health clinics.

The materials look pretty basic, but I was hoping for some recommendations on the shield material itself. We don't often deal with lean or polycarbonate thin enough for these shields. I assume anything thin enough to serve this purpose would come on a roll, but not sure the best place to source these rolls.

Cutting is the other question. We recently purchased a Summa S Class Series S2T160. We bought it for die-cutting labels and vehicle graphics, but wondering if anyone has had success on any polycarbonate-like materials.

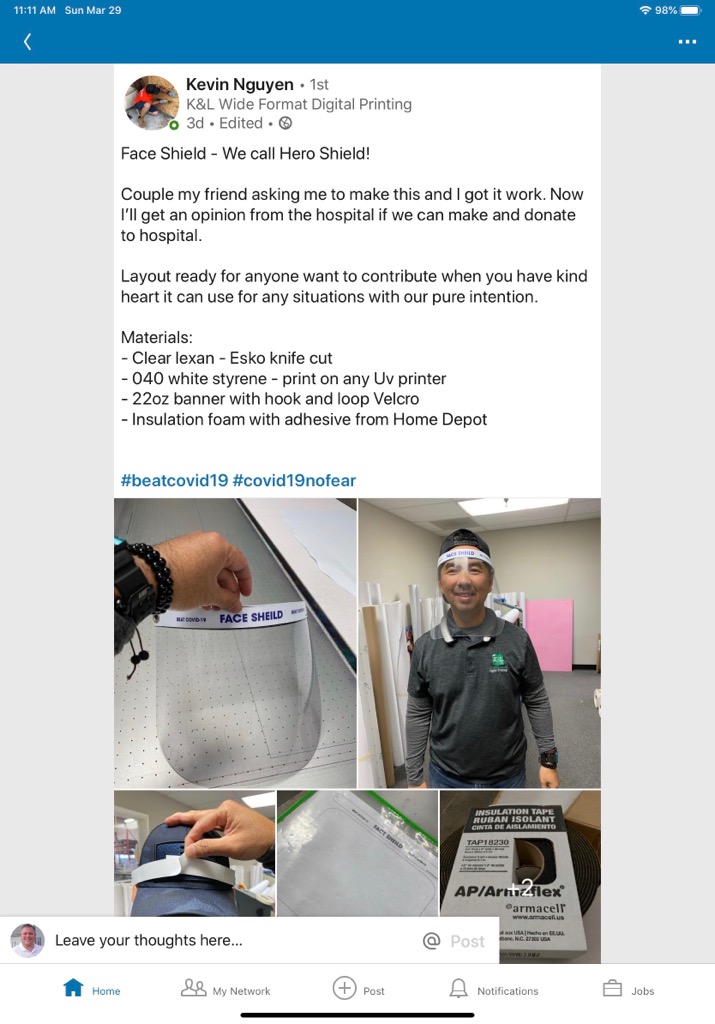

I'm including an example of what I am talking about. Please send along any input you have and please remember that this is not at all what we are set up to do, so bear with me on my lack of experience.

I'm sure everyone here has seen or at least heard about other industries jumping into the fight against Covid-19. Here at our little shop, we are hoping to jump in and help out if we can. I have come across some articles and videos online about producing your own protective face shields. We want to produce and distribute some of these at no charge for our local hospital and health clinics.

The materials look pretty basic, but I was hoping for some recommendations on the shield material itself. We don't often deal with lean or polycarbonate thin enough for these shields. I assume anything thin enough to serve this purpose would come on a roll, but not sure the best place to source these rolls.

Cutting is the other question. We recently purchased a Summa S Class Series S2T160. We bought it for die-cutting labels and vehicle graphics, but wondering if anyone has had success on any polycarbonate-like materials.

I'm including an example of what I am talking about. Please send along any input you have and please remember that this is not at all what we are set up to do, so bear with me on my lack of experience.