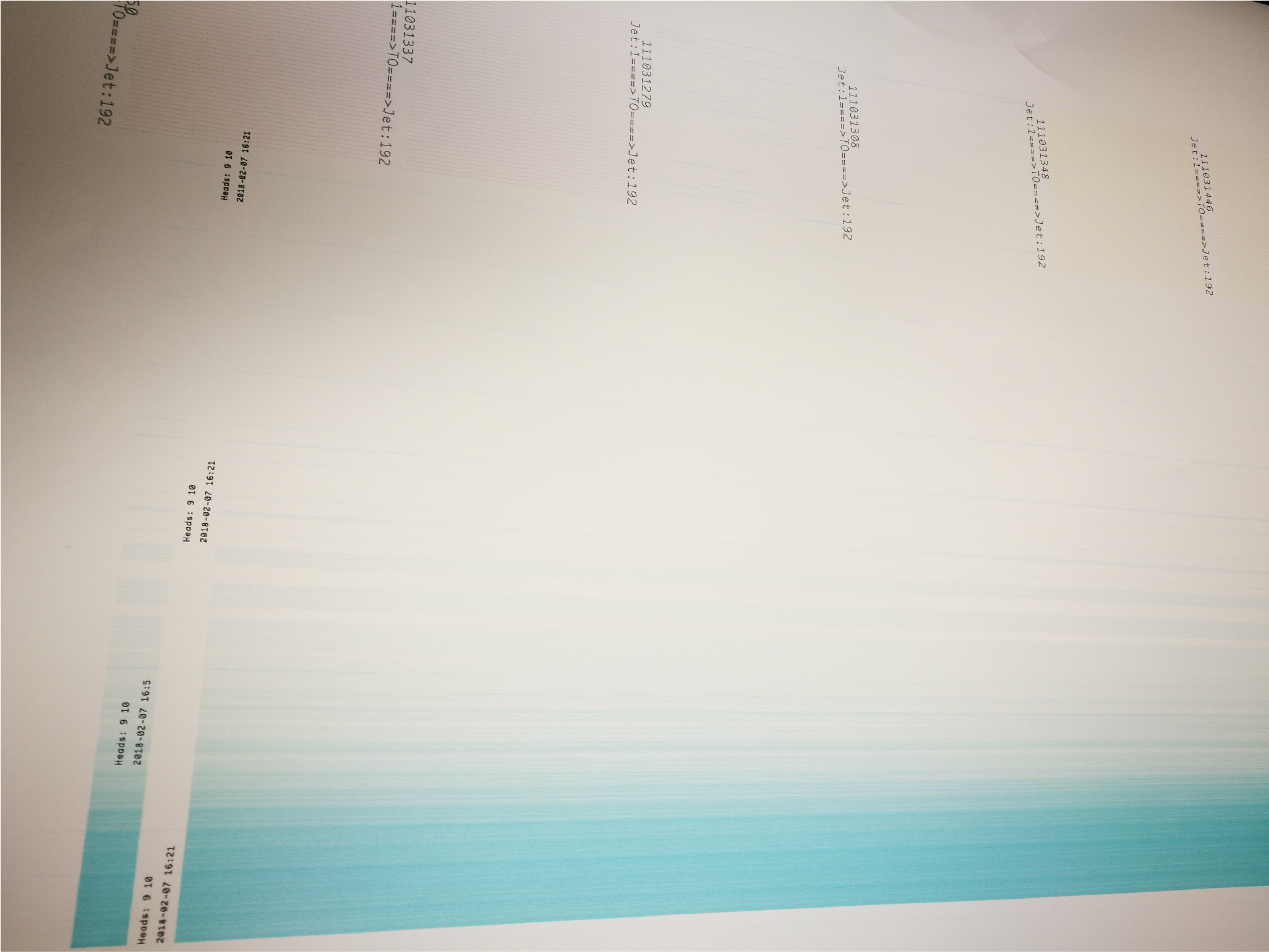

Problems started with LC suddenly not printing due to no ink in head/reservoir. Heads filled if we did fill and/or purge trough maintenance menu but didn't fill by itself during printing. Tech was here last week, changed the thermistor(-s) without result. He couldn´t find out what was wrong.

Now problem has worsened, and LC heads doesn't seem to hold the ink either. It splurts all of it out when we try to print a primebar. Other heads are ok. What is this?!

Edit: the LC heads are losing ink even when just parked at the carrige station. I se droplets hanging from under the heads.

Now problem has worsened, and LC heads doesn't seem to hold the ink either. It splurts all of it out when we try to print a primebar. Other heads are ok. What is this?!

Edit: the LC heads are losing ink even when just parked at the carrige station. I se droplets hanging from under the heads.

Last edited: