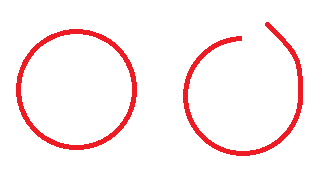

I'm looking to improve the quality of our cut. Currently using the GX24 (Now rarely) and the SP300v for cutting only. We are doing very intricate cuts such as mobile phone wraps etc. We get issues such as

- Circles often don't join, example.. (Ignore my paint skills!) - Weeding is a chore! we would leave some of it to the customer but often it doesn't cut deep enough depending on the thickness of the material, which snaps if too thick, or accuracy isn't the best, and lines get missed or circles don't join as above

- The shinier the material the less accurate the cut!

- The longer the cut the less accurate!

Wondering if I should quit on these plotters and try to find a flatbed solution. Or whether we can achieve 100% accuracy by persevering with what we have. In all honesty, not sure if the comp is lurking but their quality is smashing ours out of the water. Have done larger cuts for 5+ years but these new small intricate cuts are a stumbling block

but their quality is smashing ours out of the water. Have done larger cuts for 5+ years but these new small intricate cuts are a stumbling block

- Circles often don't join, example.. (Ignore my paint skills!) - Weeding is a chore! we would leave some of it to the customer but often it doesn't cut deep enough depending on the thickness of the material, which snaps if too thick, or accuracy isn't the best, and lines get missed or circles don't join as above

- The shinier the material the less accurate the cut!

- The longer the cut the less accurate!

Wondering if I should quit on these plotters and try to find a flatbed solution. Or whether we can achieve 100% accuracy by persevering with what we have. In all honesty, not sure if the comp is lurking