Unfortunately the capacitor shown isn't an electrolitic cap.. It looks like a tantalum cap - these are far more sensitive to over voltage than electrolytics. I'd guess that the psu is failing which probably does have electrolytics in them.. Their ESR value has probably changed and ac ripple is getting through to the main board.

Check the psu and replace all the electrolytics - they'll be aluminium tubes with Heatshrink sleeves on them - they don't need to have popped to be bad.

A simple check is to put a meter in ac mode on the dc rails - it'll how show much ac is present (should be very very low).

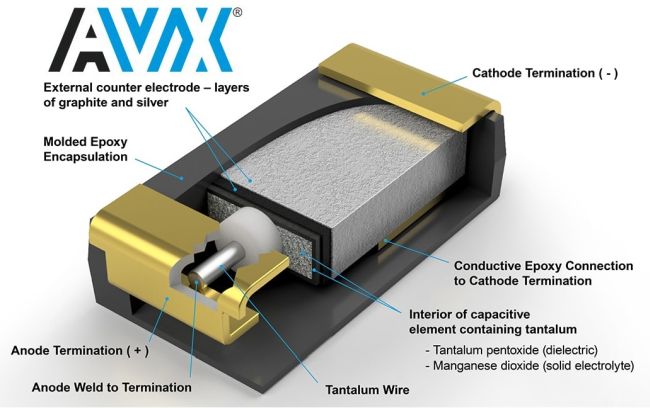

Tantalum capacitor failure modes and causes such as high ESR (equivalent series resistance), high voltage, leakage current and quality.

www.onelectrontech.com

The picture it shows is a modern surface mount cap, but it's the same as the older leaded versions.