artbot

New Member

continuation from this old thread:

http://www.signs101.com/forums/showthread.php?t=96324&highlight=blank

_______________________________________________________________

after new encoder sensor, taking out the MB and slider board getting them back from macmedia as "fine", the printer is still broken.

i'm going to update my firmware to 7.7.

______________________________________________________________

using the F/W update tool from the yahoo jv3 board. but having issues.

(jv3 160sp, v. 7.1, updating to 7.7 in hopes of curing several issues)

press remote/local during boot

printer reads "ram check"

then reads "transmit data"

i go to the F/W tool. choose JV3_FROM V600 then "upload" i here *beep*.

pc reads "can not receive data. check the status of the printer"

printer reads "F/W updating, E74 TRANS DATA"

serv' manual says E74= "Data received are not the program file/Check the version updating file"

http://www.signs101.com/forums/showthread.php?t=96324&highlight=blank

_______________________________________________________________

after new encoder sensor, taking out the MB and slider board getting them back from macmedia as "fine", the printer is still broken.

i'm going to update my firmware to 7.7.

______________________________________________________________

using the F/W update tool from the yahoo jv3 board. but having issues.

(jv3 160sp, v. 7.1, updating to 7.7 in hopes of curing several issues)

press remote/local during boot

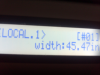

printer reads "ram check"

then reads "transmit data"

i go to the F/W tool. choose JV3_FROM V600 then "upload" i here *beep*.

pc reads "can not receive data. check the status of the printer"

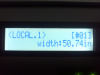

printer reads "F/W updating, E74 TRANS DATA"

serv' manual says E74= "Data received are not the program file/Check the version updating file"

Last edited: