WrapperX

New Member

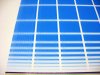

Ok, so attached are a couple of pictures of a morning routine we've started recently to correct an issue with our color Cyan.

For a short while, in the morning when we first fire up the printer and get it all set for its first print file of the day, I have noticed that the Cyan head fires irratically and gives a blue halo/haze around anything printed with that color. Also the ink ribbon prints in a staggered pattern: Looks like a zig zag or saw pattern with each pass in bi directional passes. \ on the left pass and a / on the right pass so the cyan ribbon kinda looks like:

/

\

/

\

Strangely though after about 5 or 6' of printing; the Cyan color corrects itself and is just fine for the rest of the day. But that first print and that first 5' is colored in a cyan haze.

The other day it was the worst I had seen so we created a block of color 25" wide using 100% Cyan - No other colors. For the last couple of days I run this in the morning and it runs 25" wide by however long it takes to "fix" itself. Now I am aware that we need to run a line cleaning/nozzle cleaning using cleaning cartridges and we are awaiting those cartridges in the mail. However, if this is only cause by partially clogged nozzles and a cleaning cycle can fix this - then I will be surprised. Although my inclination is that there is something wrong with the head, I was thinking, if its the head, why does it correct itself after a matter of linear feet printed? Why wouldn't it be malfunctioning continously. Then we thought it might be the capping station creating some sort of film or surface clog and that it takes a couple of feet to "blast" that film off. But it also seems way to uniformed way of printing to be a random film or residue from sitting over night. We also thought it might be the carridge mother board but if it were the board why isn't it happening to the other colors??

I am posting to see if any one else has seen this issue and if they have any input on what you see.

Thanks

Bad Cyan 1 is the first/worst print and Bad Cyan 3 is when it corrected itself in about 7' of printing today.

For a short while, in the morning when we first fire up the printer and get it all set for its first print file of the day, I have noticed that the Cyan head fires irratically and gives a blue halo/haze around anything printed with that color. Also the ink ribbon prints in a staggered pattern: Looks like a zig zag or saw pattern with each pass in bi directional passes. \ on the left pass and a / on the right pass so the cyan ribbon kinda looks like:

/

\

/

\

Strangely though after about 5 or 6' of printing; the Cyan color corrects itself and is just fine for the rest of the day. But that first print and that first 5' is colored in a cyan haze.

The other day it was the worst I had seen so we created a block of color 25" wide using 100% Cyan - No other colors. For the last couple of days I run this in the morning and it runs 25" wide by however long it takes to "fix" itself. Now I am aware that we need to run a line cleaning/nozzle cleaning using cleaning cartridges and we are awaiting those cartridges in the mail. However, if this is only cause by partially clogged nozzles and a cleaning cycle can fix this - then I will be surprised. Although my inclination is that there is something wrong with the head, I was thinking, if its the head, why does it correct itself after a matter of linear feet printed? Why wouldn't it be malfunctioning continously. Then we thought it might be the capping station creating some sort of film or surface clog and that it takes a couple of feet to "blast" that film off. But it also seems way to uniformed way of printing to be a random film or residue from sitting over night. We also thought it might be the carridge mother board but if it were the board why isn't it happening to the other colors??

I am posting to see if any one else has seen this issue and if they have any input on what you see.

Thanks

Bad Cyan 1 is the first/worst print and Bad Cyan 3 is when it corrected itself in about 7' of printing today.