Hello,

Not sure if anyone here has experienced this issue...

I have one magenta (far right) that seems to be starving everyday practically, but everytime I do a hard clean, the magenta comes back to life.

I was considering popping off the damper and try to inject cleaning solution into the nipple with hopes to unclog it. But of course I'm considered that if I do that, I may open up another can of problems.

Anyone have suggestions?

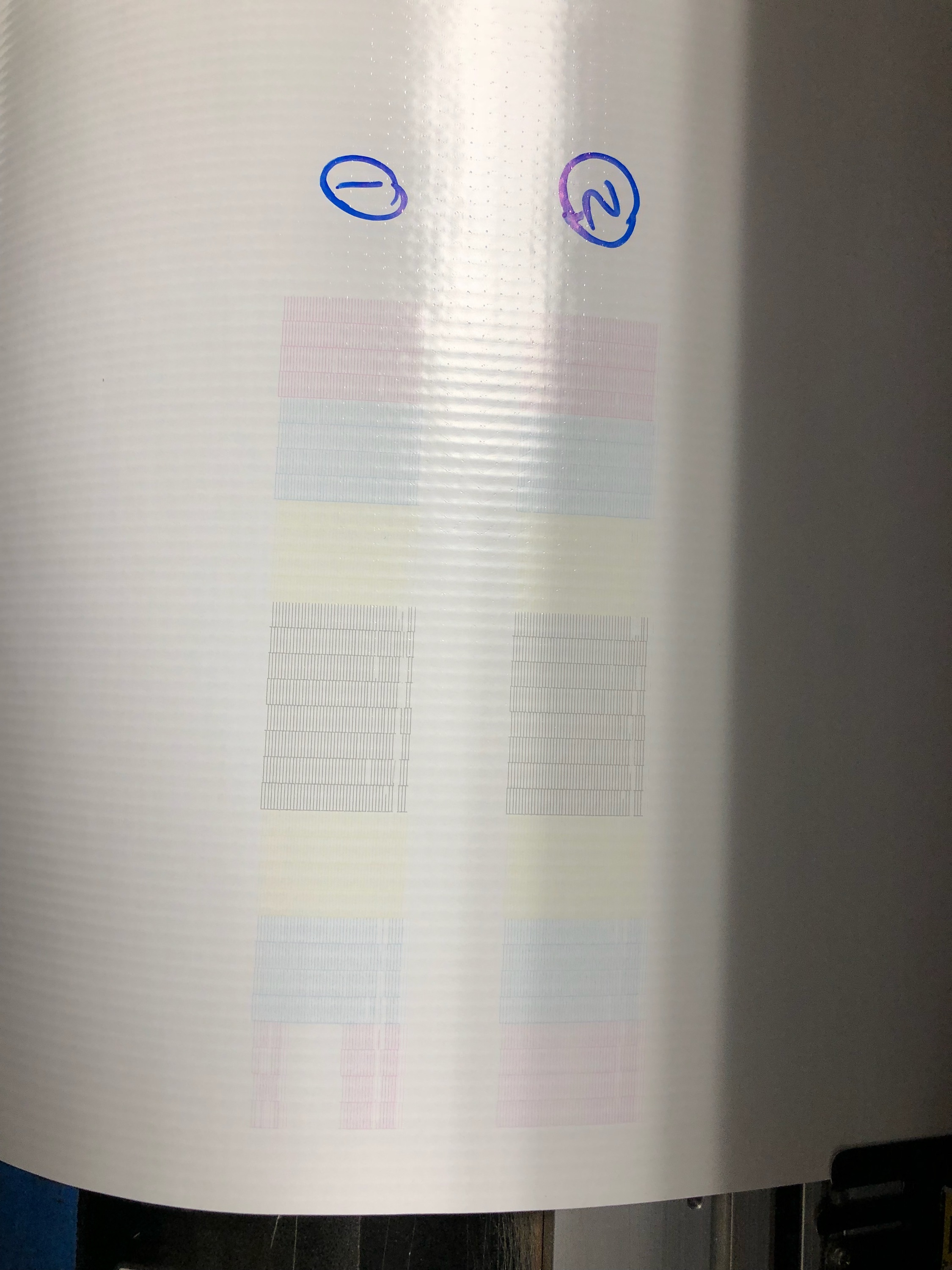

I attached a photo for reference. Test draw #1 is before the hard clean, and Test draw #2 is after the hard clean.

Take note that some other colors aren't at 100% but it's the magenta I am having the ink starvation with.

Not sure if anyone here has experienced this issue...

I have one magenta (far right) that seems to be starving everyday practically, but everytime I do a hard clean, the magenta comes back to life.

I was considering popping off the damper and try to inject cleaning solution into the nipple with hopes to unclog it. But of course I'm considered that if I do that, I may open up another can of problems.

Anyone have suggestions?

I attached a photo for reference. Test draw #1 is before the hard clean, and Test draw #2 is after the hard clean.

Take note that some other colors aren't at 100% but it's the magenta I am having the ink starvation with.