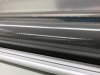

For the past few weeks we have been trying to dial in our Enduralam3 BU-1700 64" Cold laminator. We have many years of experience laminating and had an Enduarlam machine before that we had no issues with. For some reason, Tension, roll pressure or other we have trouble getting a clean run on anything longer than 60 inches. It starts out great but as the material runs we start to get bunching of the laminate which once it starts we can't seem to recover. On this machine the film strings under a chrome tension bar which seems to flex in the center because it is so tight. (see photo and that is only 30")

Any feeback would be appreciated as I have a ton of prints to laminate and I am totally freaked out about scrapping these prints due to be installed before end of week. I have attached photos of what the material is doing after a run of 72". The laminate is Avery DOL 1360Z cast.

Any advice, suggestions or feedback would be appreciated.

Any feeback would be appreciated as I have a ton of prints to laminate and I am totally freaked out about scrapping these prints due to be installed before end of week. I have attached photos of what the material is doing after a run of 72". The laminate is Avery DOL 1360Z cast.

Any advice, suggestions or feedback would be appreciated.