Hi there,

I am fairly new to this whole game. I got a job making decals for a pressure washing company, basically had 3 hours of training on all the machines and have been left to my own devices for the past 8 months. No one else who works here has had much experience with the machines either so it's been trial and error when something goes wrong.

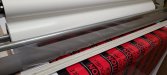

The laminator here is a GBC Professional 1064WF, its old as heck, I think, and probably little to no maintenance done to it.

It is wrinkling EVERYTHING, one side will start to get loose, I turn the tension down, nothing, I turn the tension up, nothing. I cut the laminate and re-feed it and it fixes it for about 3 feet before it wrinkles again. I waste so much vinyl and laminate.

Does anyone have any suggestions?

I've gone through past posts searching for answers but no solutions have worked for me thus far

I am fairly new to this whole game. I got a job making decals for a pressure washing company, basically had 3 hours of training on all the machines and have been left to my own devices for the past 8 months. No one else who works here has had much experience with the machines either so it's been trial and error when something goes wrong.

The laminator here is a GBC Professional 1064WF, its old as heck, I think, and probably little to no maintenance done to it.

It is wrinkling EVERYTHING, one side will start to get loose, I turn the tension down, nothing, I turn the tension up, nothing. I cut the laminate and re-feed it and it fixes it for about 3 feet before it wrinkles again. I waste so much vinyl and laminate.

Does anyone have any suggestions?

I've gone through past posts searching for answers but no solutions have worked for me thus far