jtiii

I paid good money for you to read this!

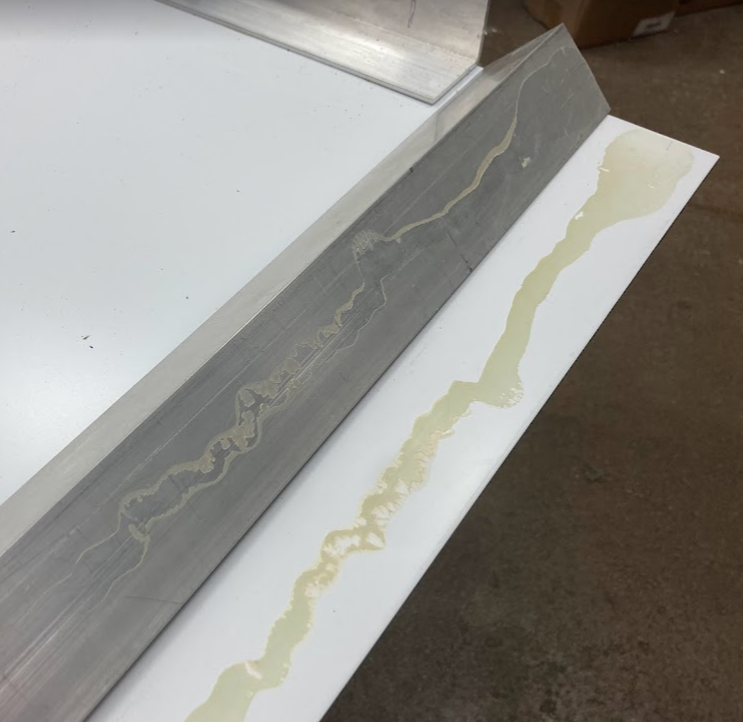

I was gluing 2" aluminum angle to acm to make returns. Used Lord's 406/19 (not expired). Lightly scuffed the angle and wiped it with ispropyl. Same for the acm. Squeezed out a mixing nozzle's worth first to ensure full mix. Clamped for 24 hours. Today I went to move the sign and the pieces snapped off with not much force. It mostly but not exclusively failed on the angle side. The adhesive is cured.

I've used Lord's a few times before without issue but this is my first time making returns and my first time experiencing failure. Can anyone tell me what I did wrong? As always, the client wanted this up yesterday

I've used Lord's a few times before without issue but this is my first time making returns and my first time experiencing failure. Can anyone tell me what I did wrong? As always, the client wanted this up yesterday