gnubler

Active Member

I'm in the beginning stages of putting together a donor recognition display and would like some feedback on choosing the best materials and the best method of mounting it on the wall.

It's going to measure 3 ft wide by 5 ft tall, a single main panel rigid enough to support about two dozen individual acrylic nameplates that will be attached with standoffs. The main panel will be contour cut along the top edge to look like mountains, printed vinyl applied, and needs to be strong enough to accommodate all the screws for the standoffs. What would you use? I considered 6mm Dibond but wondering if that would make it look 'cheap' unless I paint the edges or wrap the vinyl around.

I want to calculate the total weight of the piece before I even start production. Would you use a French cleat bracket on the back, or what? I went on a site visit to check out the installation wall - it's only going to span one metal wall stud in the center somewhere and the rest will have to be drywall toggles.

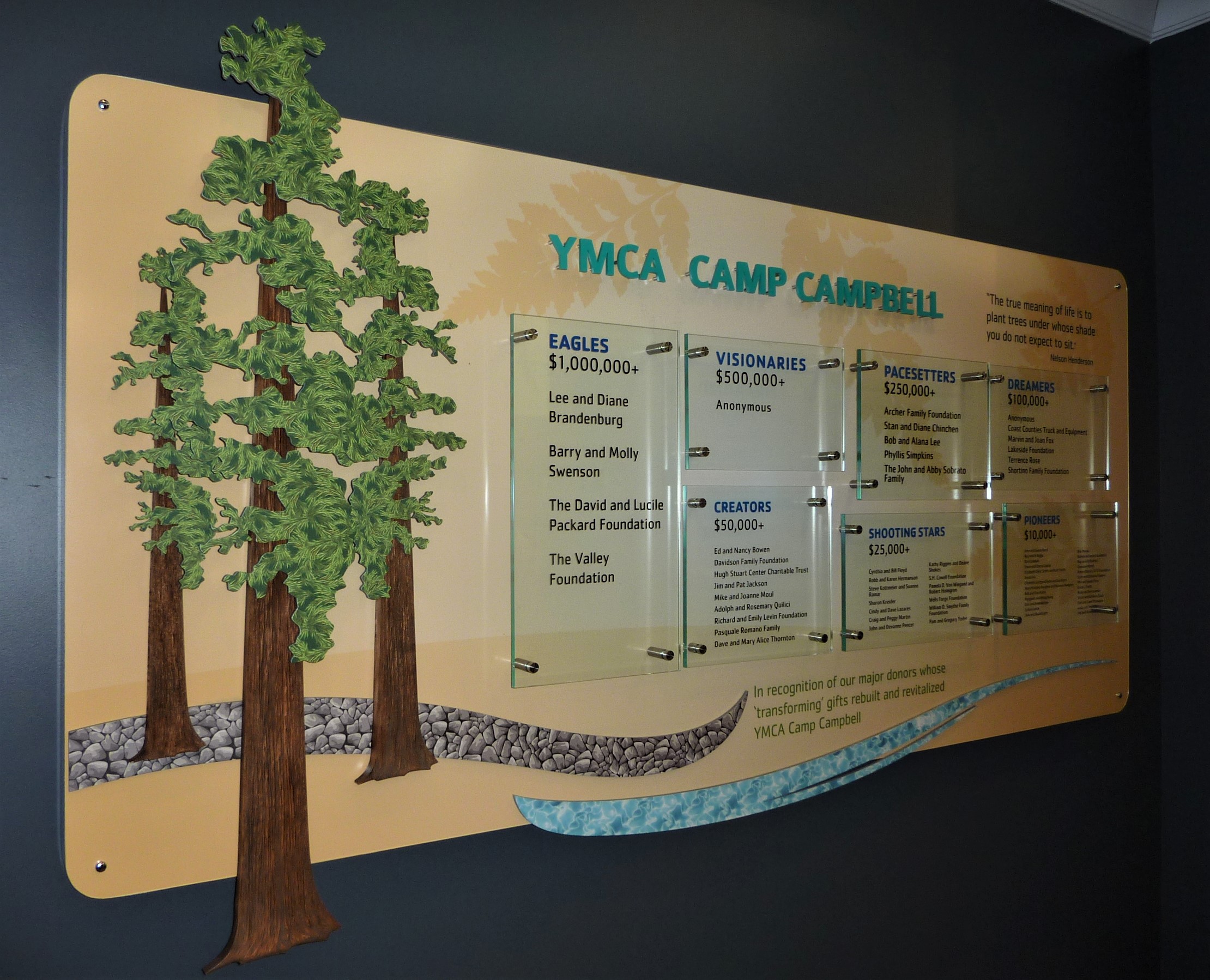

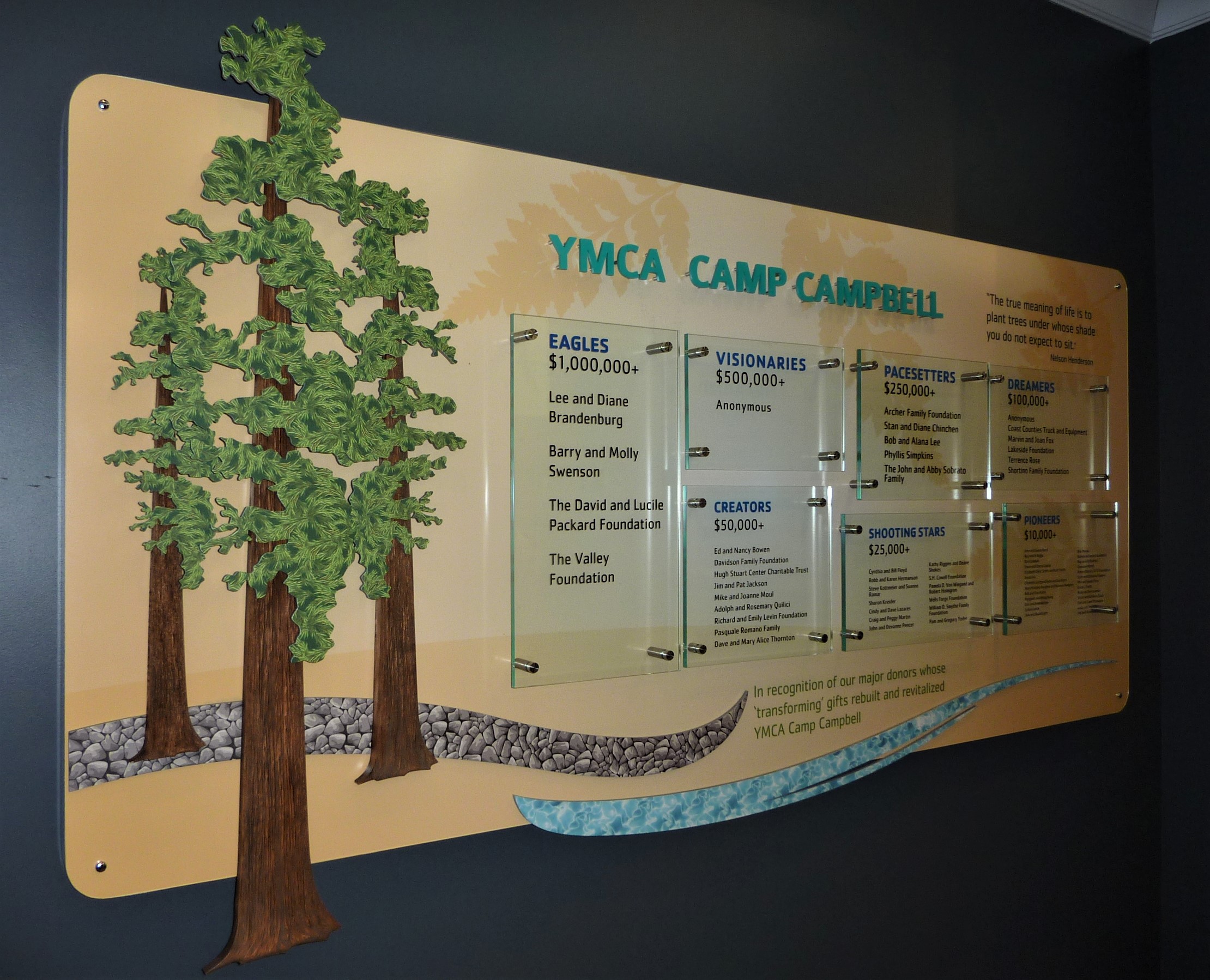

Here's an example I found online of a similar concept - one main panel with dimensional pieces attached. Any ideas on what the main panel is and how it was mounted on the wall?

It's going to measure 3 ft wide by 5 ft tall, a single main panel rigid enough to support about two dozen individual acrylic nameplates that will be attached with standoffs. The main panel will be contour cut along the top edge to look like mountains, printed vinyl applied, and needs to be strong enough to accommodate all the screws for the standoffs. What would you use? I considered 6mm Dibond but wondering if that would make it look 'cheap' unless I paint the edges or wrap the vinyl around.

I want to calculate the total weight of the piece before I even start production. Would you use a French cleat bracket on the back, or what? I went on a site visit to check out the installation wall - it's only going to span one metal wall stud in the center somewhere and the rest will have to be drywall toggles.

Here's an example I found online of a similar concept - one main panel with dimensional pieces attached. Any ideas on what the main panel is and how it was mounted on the wall?