Tim Aucoin

New Member

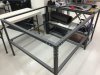

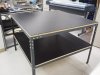

I had my brother (who is an iron artist) build me another work table. He built me a 4' x 8' table 3 years ago (I had posted pics of this one back then)... This time I needed a 4' x 4' one. He builds them pretty darn strong and sturdy for sure! Now just to get the wood for the top and middle shelves!