-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plexiglas Standoff Signs w/ Frosted

- Thread starter Texas_Signmaker

- Start date

Texas_Signmaker

Very Active Signmaker

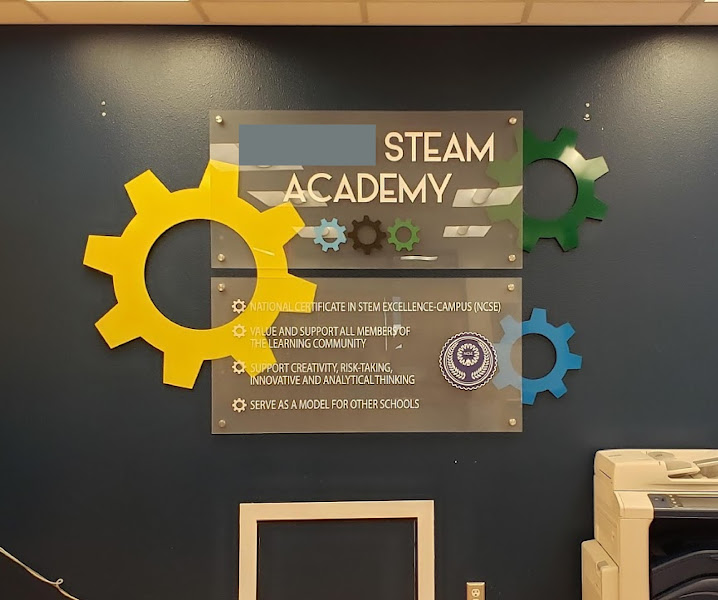

Here it is...

Last edited:

Texas_Signmaker

Very Active Signmaker

stud mounted acrylic from Gemini. The other gears on the hallways are coroplast with VHB.

Spelling and grammatical errors are for the kids to discover.

Spelling and grammatical errors are for the kids to discover.

signage

New Member

Spelling and grammatical errors are for the kids to discover.

Likely excuse :-{){

Bigdawg

Just Me

In addition to this, if you flame polish acrylic and then wet install frost expect potential issues.

I did such, and wet applied frost film with rapidtac/soapy water. The acrylic ended up with microfizzure cracks inward from the edges.

I believe that because the flame polishing melts and affects the composition of the acrylic on a microscopic level, the chemical application whether it's soap or anyting can have a negative effect, especially once it has been squeegeed with some pressure. My guess is also the introduction of ISO alcohol for cleaning or in mix. I'd agree the p95 option as shown or a Frost vinyl applied to acrylic that has not been flame polished.

As far as cleaning acrylic pieces with a flame-polished edge... we use Mineral Spirits as recommended by our acrylic guy. Yes, we have an acrylic guy and that's all he does. After ruining several custom cut, polished pieces we got smart enough to ask him what he uses. We still use it sparingly, but no cracks or issues since we switched over.

Texas_Signmaker

Very Active Signmaker

Did you use the glossy side out? Kind of defeats the purpose of the material, doesn't it?

Customer liked the shine on it.

Texas_Signmaker

Very Active Signmaker

the "A" in STEAM stands for "Arts"... so they added that inI think this is awesome. I do feel like there is a better word to start all of these statements with. Use this. Use that. Is it just me? But really great work.

Is STEAM a misspelling of STEM?

Honestly I didn't even read the copy... I just copy and pasted it on there. That sign had like 10 revisions after it was all said and done.

JTBoh

I sell signage and signage accessories.

In addition to this, if you flame polish acrylic and then wet install frost expect potential issues.

I did such, and wet applied frost film with rapidtac/soapy water. The acrylic ended up with microfizzure cracks inward from the edges.

I believe that because the flame polishing melts and affects the composition of the acrylic on a microscopic level, the chemical application whether it's soap or anyting can have a negative effect, especially once it has been squeegeed with some pressure. My guess is also the introduction of ISO alcohol for cleaning or in mix. I'd agree the p95 option as shown or a Frost vinyl applied to acrylic that has not been flame polished.

Soap and water is fine, BUT alcohol at any step of the process, even before, can cause the cracking.

That said - one of these days i'll get around to using that as part of the design, somehow. Intentionally cracked and still structurally sound.