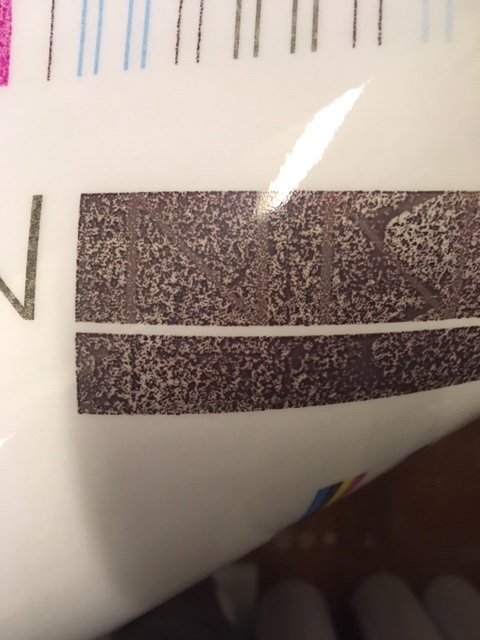

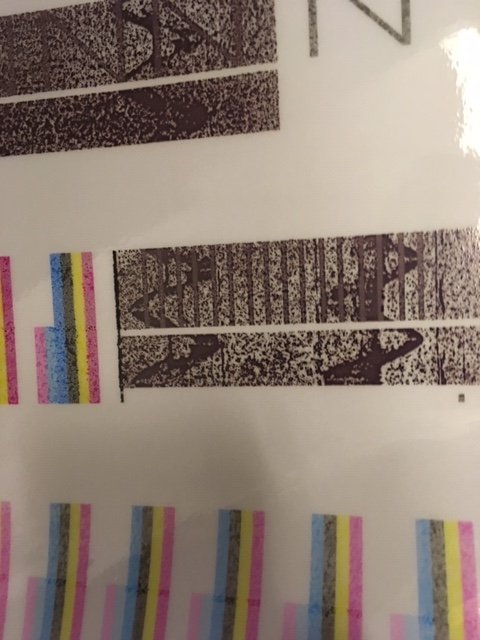

I'm trying to print on static cling. The brand of material is Digijet. I have a HP latex 315. It's giving me weird printing results. I ran a head cleaning and calibration. but it did not improve anything. I'm attaching pictures of the problem here. I suspect I need a better profile. The Digijet profile I got is named GF 207. Any generic profiles or other ideas for this problem....?

-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Printing on static cling problems

- Thread starter depps74

- Start date

WhiskeyDreamer

Professional Snow Ninja

I'm not familiar with inkjet printing, but this looks like the ink is not bonding with the static cling. Is the static compatible with the type of ink you're using? Does the ink print fine on other materials?

Christian @ Visual Graphx

Active Member

how old is the roll? Static Cling has a very short shelf life typically.

signman315

Signmaker

Looks like the latex printer heat settings aren't hot enough...I would get those same results when my heat settings weren't hot enough. If you can't go hotter then you have to slow it down. There's not enough time/heat to allow the ink to dry into place before it goes into curing phase. I'm used to using the old L28500 which didn't have the optimizer ink, but instead had two heat zones (drying and curing). They've since eliminated the drying zone and replaced it with optimizer ink. So I guess it could also be not enough optimizer in your profile but you would need to check with someone other than myself on that one. Your profile could have ink limits that are too high for that media, you should be able to use the same profile for SAV as static cling if you get your heat/speed/optimizer settings right. The bottom line is that the ink isn't drying fast enough and is experiencing a huge dot gain before it cures. When you see those zig-zag lines it's a tell tale drying/curing issue on the HP latex machines. Plasticizer could also be an issue as Unclebun mentioned but I personally have only had that issue with banner not static cling. I'm using solvex brand static cling. Hope it helps!

Solventinkjet

DIY Printer Fixing Guide

Static cling is notoriously rough to work with but that is really bad. I would think it has to be either not compatible with the ink you are using, defective or as stated above, really old.

It's about 6 months old. I printed on it when we first got it and it printed great. That would explain it though. Will the alcohol cure the age problem?Try cleaning a piece of the vinyl with 91% isopropyl alcohol and test print it. If it prints better, the problem may be the plasticizer has migrated to the surface.

It's about 6 months old. I printed on it when we first got it and it printed great. That would explain it though. Will the alcohol cure the age problem?Static cling is notoriously rough to work with but that is really bad. I would think it has to be either not compatible with the ink you are using, defective or as stated above, really old.

It's about 6 months old. I printed on it when we first got it and it printed great. That would explain it though. Will the alcohol cure the age problem?how old is the roll? Static Cling has a very short shelf life typically.

petepaz

New Member

static cling can be a pain but 6 months old should not be bad. i am not familiar with latex printers but with our solvent printers we sometimes have to use the high quality print mode to get a good print. we are printing with roland solvent printers and i will use a clear vinyl profile on high quality that usually give us a good print

signman315

Signmaker

I agree, 6 months shouldn't be a plasticizer issue...although with that said there are some really poor quality materials out there so who knows. I've seen all kinds of plasticizer problems on banner materials but never static cling. I use Solvex and have had rolls older than a year not give me any trouble when printing with a Mimaki and/or HP latex. Those zig zag lines in the OP photo are very typical indicators of curing issues on an HP latex. It's funny because the first time I saw the zig zags on the latex machines I interpreted as too high of heat...it almost looked like the ink was drying too fast and had no dot gain, but I was completely wrong it's too low heat (aka too fast speed) and the ink is settling into the valleys of the surface of the substrate.static cling can be a pain but 6 months old should not be bad. i am not familiar with latex printers but with our solvent printers we sometimes have to use the high quality print mode to get a good print. we are printing with roland solvent printers and i will use a clear vinyl profile on high quality that usually give us a good print

Solventinkjet

DIY Printer Fixing Guide

Just keep in mind that OP may have had this roll for 6 months but who knows how long the dealer had it on the shelf.

I only ever get the zig zag lines from the rollers on old or really cheap stuff (plasticizers). The rest of it however looks like incompatibility issue. Have you tried to do an optimizer test to see if increasing or decreasing the optimizer makes any difference?

Typically that blotchiness is indicating that the ink doesn't like the media and will tend to pool together into those blobs and leaving empty spaces between them. Optimizer is supposed to help with that and I have had issues where I had to adjust the optimizer level to get rid of the blotches. However my cases were nowhere near that bad. If optimizer or the amount of ink don't help with that then I would say the media is bad.

Does the ink appear to lay smoothly before it reaches the heat? Or does that only happen after it passes through the heat.

To me it looks like the media is past shelf life. I've had banner we only had for 3-4 months that caused something similar, also printed just fine when we first got it.

Typically that blotchiness is indicating that the ink doesn't like the media and will tend to pool together into those blobs and leaving empty spaces between them. Optimizer is supposed to help with that and I have had issues where I had to adjust the optimizer level to get rid of the blotches. However my cases were nowhere near that bad. If optimizer or the amount of ink don't help with that then I would say the media is bad.

Does the ink appear to lay smoothly before it reaches the heat? Or does that only happen after it passes through the heat.

To me it looks like the media is past shelf life. I've had banner we only had for 3-4 months that caused something similar, also printed just fine when we first got it.

signman315

Signmaker

Good point, I've had rolls of laminate delivered to me that are so old that the backing is yellowed and it won't release from the liner without ripping!Just keep in mind that OP may have had this roll for 6 months but who knows how long the dealer had it on the shelf.

Superior_Adam

New Member

I have a HP 560 and can create my own profiles and set the speed and heat temps manually. Will your machine allow you to not use a provided profile and make your own. If you can I would do that, I have created my own profiles for every media that we use. When we first got the machine I tried the exact supplied profiles and was not getting good results on anything until I manually set me own.

AGCharlotte

New Member

odd... I've had the same roll of Briteline cling for well over a year and I've had no issues when I drag it out for onesie twosies.