Ramsey_Wraps

New Member

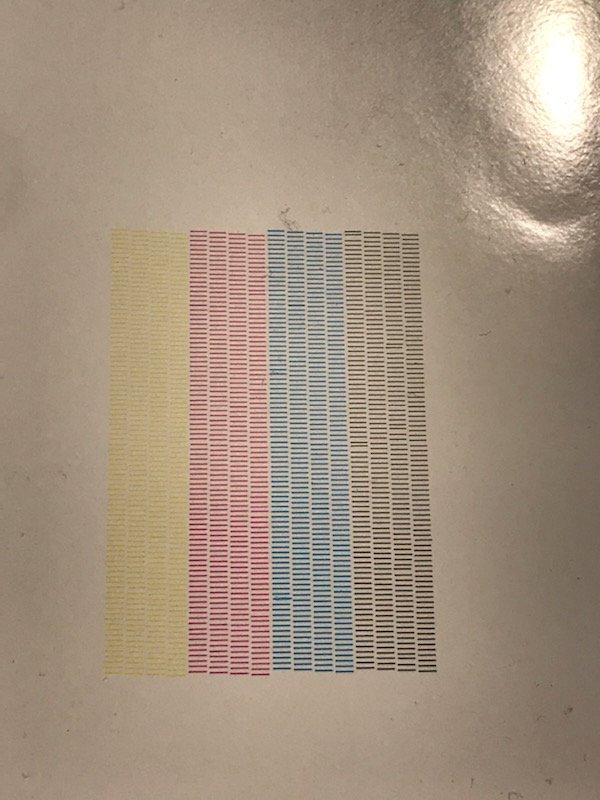

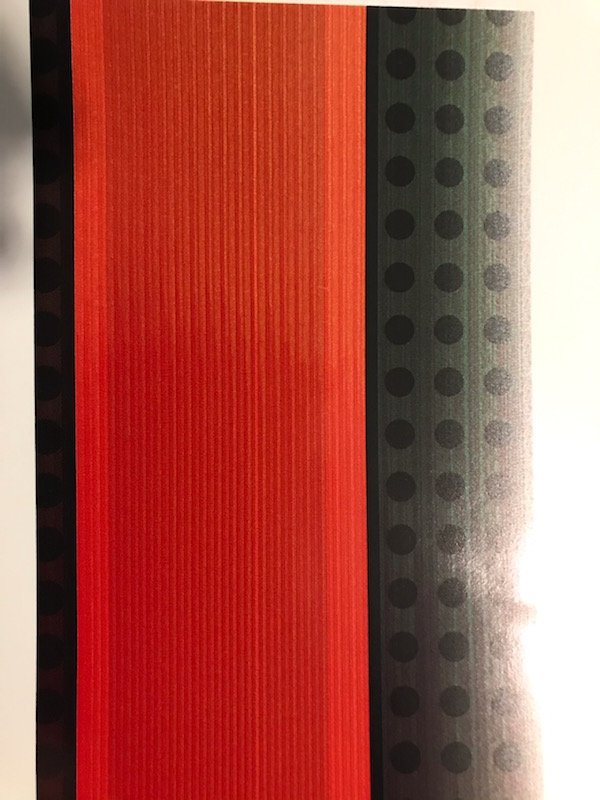

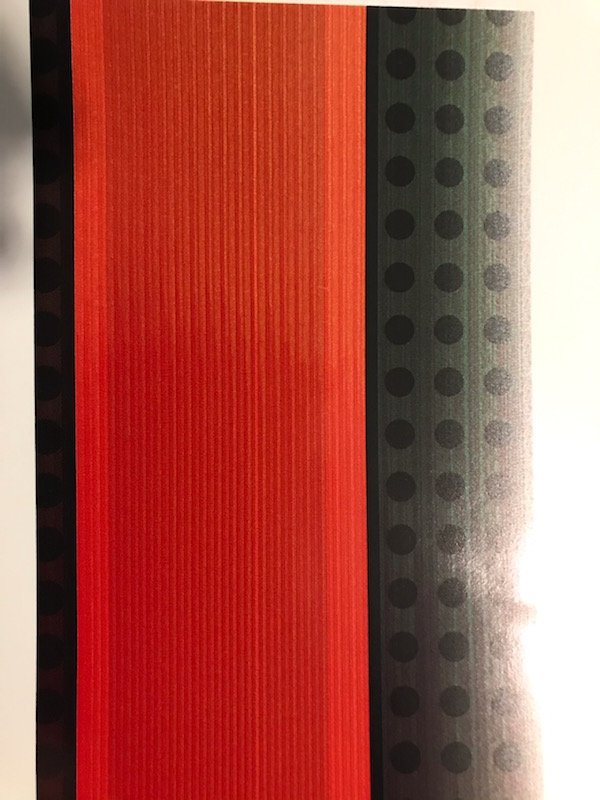

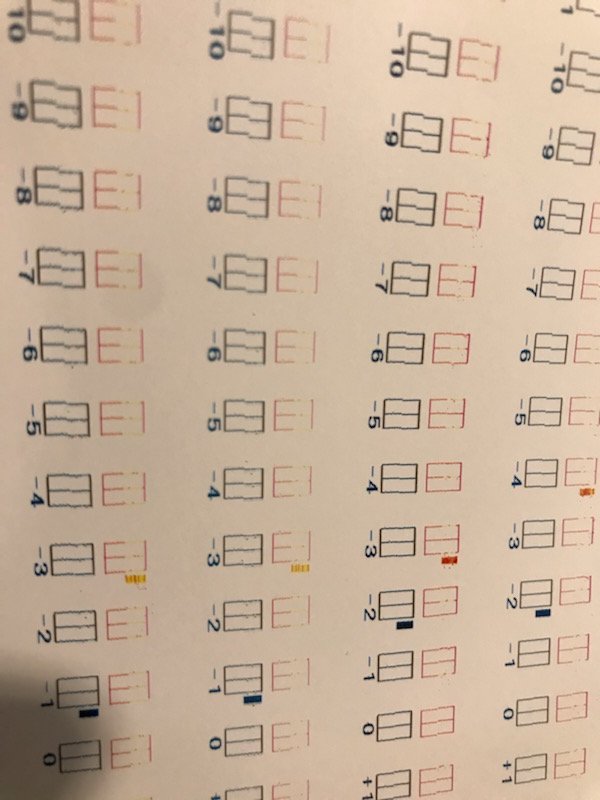

I have a Roland SP-540v and I can not get it to print right. I have attached pictures of the issue and test prints for calibration. Have done all the regular maintenance but nothing seems to help.

The Bidirectional adjust print drops out the magenta row so bad I can't tell how to adjust it...

Please any help would be appreciated....

The Bidirectional adjust print drops out the magenta row so bad I can't tell how to adjust it...

Please any help would be appreciated....